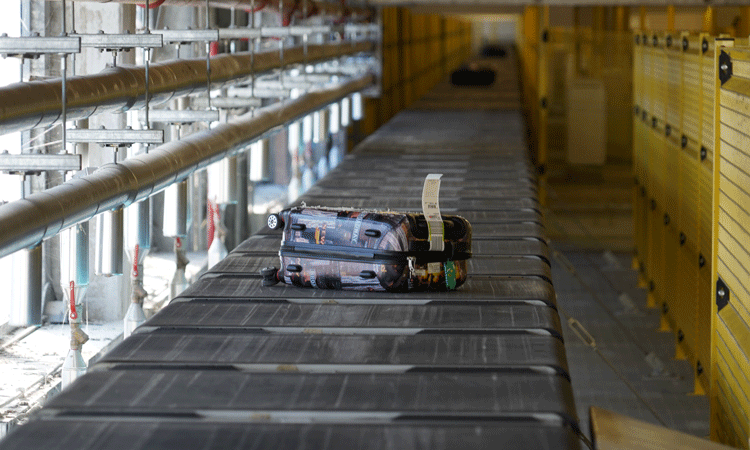

Development of a virtuous baggage handling system at Fiumicino Airport

- Like

- Digg

- Del

- Tumblr

- VKontakte

- Buffer

- Love This

- Odnoklassniki

- Meneame

- Blogger

- Amazon

- Yahoo Mail

- Gmail

- AOL

- Newsvine

- HackerNews

- Evernote

- MySpace

- Mail.ru

- Viadeo

- Line

- Comments

- Yummly

- SMS

- Viber

- Telegram

- Subscribe

- Skype

- Facebook Messenger

- Kakao

- LiveJournal

- Yammer

- Edgar

- Fintel

- Mix

- Instapaper

- Copy Link

Posted: 17 June 2022 | Marco Sbrenni | No comments yet

Marco Sbrenni, Baggage Handling Expert at Aeroporti di Roma, tells International Airport Review about the important investments that have been made into Fiumicino airport’s baggage operations over the years.

Credit: Aeroporti di Roma (ADR)

Leonardo da Vinci International Airport, located in the municipality of Fiumicino, Rome, started its operations in 1960 and, since then, has embarked on a path of constant evolution both from an infrastructural point of view and in relation to activities of passenger assistance.

In this context, the management of hold baggage has been the focus of attention since the start, due to the complexity and specificities characterising this process.

Indeed, the handling of hold baggage, i.e., those not considered to have the characteristics and dimensions compatible with carriage in the cabin, has always been a source of anxiety for passengers, as well as a key element in achieving objectives in terms of operational efficiency and quality of the service, essential for all airlines.

While passengers need to be certain that they will be able to recover their goods upon arrival at their destination, the carrier on the other hand, needs to achieve stable operational performances (with reference to departing on time) and be sure that all the baggage accepted at the check-in desk is loaded in compliance with the regulations in force in terms of safety and security.

The need for innovative technologies

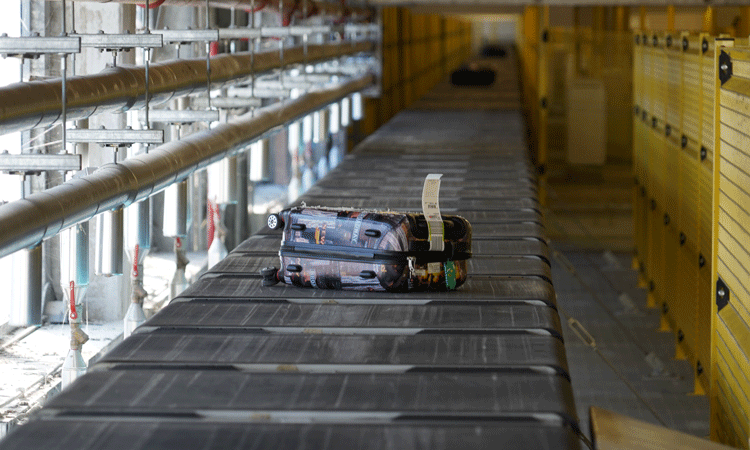

At the dawn of the air transport industry, the process of handling and sorting checked baggage was mainly manual, employing human resources who, even with the utmost commitment, were subjected to frequent human errors that caused disruptions – such as mishandled or misrouted baggage, with obvious negative implications for passengers and carriers. Hence, the need for airports to review the process by investing in infrastructure upgrades and innovative technologies capable to guarantee the automatic sorting of baggage, both upon departure and in transit.

Credit: Aeroporti di Roma (ADR)

Such investments over time have made it possible to significantly reduce inefficiencies, increasing operational performance and the quality of the service, reducing the workload of the staff employed in manual activities, simultaneously increasing the levels of safety and security.

Since the 1990s, Fiumicino Airport has been equipped with the so-called BHS (Baggage Handling System) systems for sorting baggage and the HBS (Hold Baggage Screening) systems for the x-ray control of 100 per cent of baggage upon departure.

Following the most relevant technological evolutions, important investments have been made over the years, which today allow us to operate with two BHS systems and two new generation HBS systems, of which the salient features are described below.

Credit: Aeroporti di Roma (ADR)

Fiumicino

At the dawn of the air transport industry, the process of handling and sorting checked baggage was mainly manual, employing human resources who, even with the utmost commitment, were subjected to frequent human errors that caused disruptions … Hence, the need for airports to review the process by investing in infrastructure upgrades and innovative technologies”

At Fiumicino Airport, we operate with two passenger terminals: Terminal 1, mainly dedicated to domestic and European flights, and Terminal 3, mainly dedicated to non-European flights. Both terminals are equipped with an autonomous BHS / HBS system that manages departure / transit baggage, as well as with a facility area dedicated to the delivery of arriving baggage.

The management of departing baggage is guaranteed by the following infrastructural set up:

- 14 check-in islands

- 370 check-in desks

- Two systems for sending oversized baggage

- Approximately 29 km of conveyor belts

- HBS with 16 standard three X-ray machines organised on five control levels

- Five sorting machines with a continuous ring that transport, sort and, if necessary, put the baggage back into circulation. The transport system includes a series of trolleys with ‘cross belt’ cells that move perpendicularly to the direction of the trolleys, to guarantee loading and unloading in the dedicated area. Baggage is loaded onto sorting machines from high-capacity entry lines. If the baggage must remain awaiting sorting, it is sent to an accumulation line. The purpose of these lines is to store the baggage that is introduced into the system before a staging bay dedicated to the relative flight is enabled, maintaining the full capacity of the sorting machines

- 107 between bays, carousels, and slides.

Credit: Aeroporti di Roma (ADR)

The management of arriving baggage is guaranteed by:

- 15 carousels

- Three accesses for the delivery of oversized baggage.

The total amount of baggage departing and arriving at our airport in 2019 was over 21,000,000 (the 2020 and 2021 figures are not significant due to the impact of the COVID-19 pandemic).

TAKE A READ:

Aeroporti di Roma’s commitments to SESAR projects

Aeroporti di Roma’s strategy to welcome the recovery of traffic and build the airport of the future by Marco Troncone

Fiumicino Airport joins ACI register of excellence for quality of services

Furthermore, for the day-by-day management of the BHS / HBS systems, a control room has been created, operating 24 hours a day, which allows continuous monitoring of the performance of the systems, highlighting any critical issues and timely resolution measures. Among other things, the inclusion of this structure within the larger APOC room (Airport Operations Centre) allows maximum integration with all the operational and control rooms necessary for a coordinated and effective management of airport operations.

As for the route carried out by a baggage departing from Fiumicino Airport, these are the main steps:

- Acceptance by the carrier at the check-in desk

- Insertion of a label with 2D barcode containing all the data necessary for boarding (destination airport, flight, date, etc.)

- Sending on the manifold belts to the BHS / HBS plant

- Reading, through ATR (Automatic Tag Reader) denomination arches, of the 2D barcode by the system that stores all the data necessary for sorting and the position of the baggage

- X-ray inspection of baggage by standard technology 3, to identify any prohibited objects

- Sorting of baggage

- Baggage delivery on a bay dedicated to the carrier / handler

- Reconciliation of baggage with the passenger and the flight

- Loading the baggage into a container

- Loading of the container in the hold of the plane

- Delivery of baggage to the passenger at the destination airport.

Finally, I would like to underline that the excellent performances achieved in recent years by Fiumicino Airport are not solely to be attributed to the significant investments made, but also to the close collaboration that has been established over the years between all the actors involved – i.e., the Italian Civil Aviation Authority, the airport manager, the carriers and the handlers.

Indeed, only through a profound sharing of objectives and the tireless daily work of everyone, which also exploits the important amount of data available today, is it possible to identify, share and implement actions that guarantee continuous improvement of processes.

Biography

Related topics

Baggage handling, Capacity, COVID-19, Passenger experience and seamless travel, Safety, Security, Terminal operations