Creating a first-of-its-kind LiDAR laboratory at Tampa International Airport

Posted: 4 June 2025 | Doug Wycoff | No comments yet

Doug Wycoff, Director of Digital Solutions and Innovation at Tampa International Airport, spoke with International Airport Review about the airport’s most recent innovations, including its LiDAR laboratory and their plans for a ‘dream’ baggage handling system.

What trends have you been observing among your passengers that have prompted new innovations?

Passengers are demanding ease. They want to get to their destination as simply as possible.

Passengers are demanding ease. They want to get to their destination as simply as possible. This includes things like self-service bag drops and simple e-gates. They want to move along once they arrive and avoid standing in lines, which can be frustrating. The airport is trying to streamline processes and optimise the use of self-service bag drops and other technologies.

What has your most recent successful innovation been?

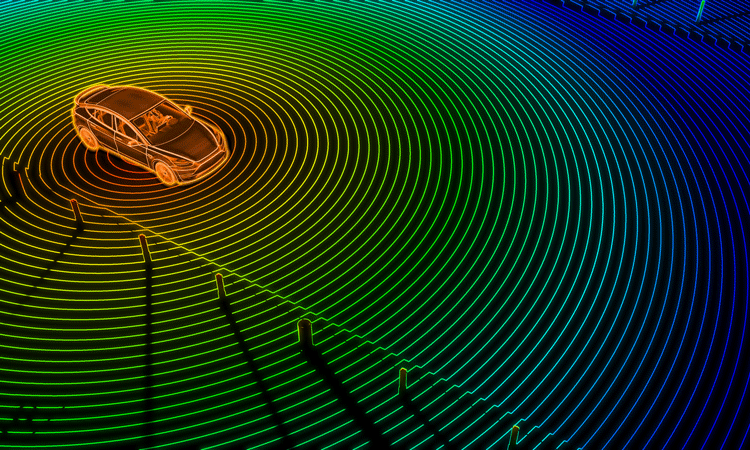

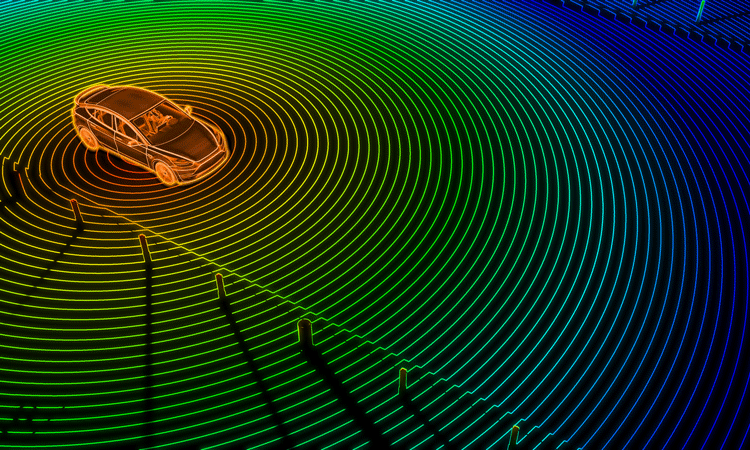

One of the successful innovations presented recently, related to optimising the roadway partnership with Indoor Labs. Road congestion is a major challenge, especially during busy periods like spring break, Thanksgiving, Christmas and New Year. By using light detection and ranging (LiDAR) technology, we can identify, and get ahead of, problems. If a threshold of cars is reached in an area within a certain time, a notification can be sent to police via text or email. Based on historical data, they know the typical traffic flow and how many cars likely go in different directions. If the traffic flow significantly exceeds the normal rate (e.g. 750-800 vehicles every 30 minutes compared to a normal 400-500), they know to proactively send someone out. This is more effective than reacting to a phone call saying there’s a backup half a mile away. They now have a dashboard providing historical data, allowing police to view hour-by-hour, year-over-year, and month-over-month traffic information, which was not previously available.

Can you put a number on the benefits in terms of efficiency savings?

The benefit in efficiency savings comes from being proactive.

Join us live: Shaping the Next Generation of Hold Baggage and Air Cargo Screening

Join us live for an insightful webinar on 11th December at 14:00 GMT, in collaboration with Smiths Detection, as we explore the strategic balance of operational efficiency, regulatory compliance, and sustainability in high-volume security environments.

This session offers a focused look into future-proofing your security strategy.

Key learning points

- Cost Reduction: Strategies to minimize bag travel time while simultaneously reducing operational costs.

- Regulatory Roadmap: Insights into the next wave of regulatory changes and their impact on future investment decisions.

- Sustainable Systems: Practical approaches to building sustainability into security systems and lowering the total cost of ownership (TCO).

- Scalable Solutions: Real-world examples of scalable systems supporting current airport growth and preparing for tomorrow.

Register now for expert insights, case studies, and actionable strategies on operational efficiency!

This process allows for adjustments to meet the needs of the staff, and they feel their voice is heard.

There isn’t necessarily a direct dollar value, but it means police officers and other personnel are not standing around unnecessarily before they are needed. Instead of simply assigning staff based on historical assumptions (e.g. “last Tuesday was busy, Joe will be out there”), notifications are sent only when needed. This is certainly a benefit of utilising LiDAR technology. Providing staff with more information so they know what problem they are addressing helps them do their job well. This process allows for adjustments to meet the needs of the staff, and they feel their voice is heard.

What challenges have you faced with this kind of implementation?

Certainly, all the work we’ve done in the LiDAR platform has been a huge pivot for us. We haven’t had a failure, but we’ve certainly had to work with our network team. We have an amazing network team who understand the bandwidth utilisation, the sheer volume these sensors bring to the table, and addressing how you move that across your network without impacting the network. They worked very closely with the vendor for data compression, how to reroute it and how to make it independent to keep saturation points from happening. One of the main issues is that the technology is changing so fast on the LiDAR side that adjusting our sensors as new technology comes out, has literally tripled in capacity in the last three years.

You’ve partnered with Indoor Lab to create a first-of-its-kind LiDAR laboratory. What kind of products will you showcase in this lab?

The airport itself is used as a ‘sandbox’. They currently have about 12 solutions running or in production in various forms. The Roadway solution is the most recent and went live on 16 April. Other solutions include:

- Shuttle lobby monitoring to gauge volume and potentially reduce/slow the number of shuttles sent to the checkpoint if capacity is reached proactively, preventing people from queuing outside the lobby

- Monitoring restaurant traffic, including volume and how long people stand in line

- Monitoring gate hold areas

- Underwing monitoring, which can track specific events like when a plane chocks at the gate, when the jet bridge, air conditioning, and fuel are connected, and when servicing begins and ends. This information can be shared with airlines at other airports (like Alaska Air in Seattle) who may not have full staff at Tampa but have contracted services, providing them with performance data via a dashboard.

These are examples of things they are developing to meet needs in the LiDAR laboratory.

What are your latest advancements in baggage technology?

A lot of the baggage technology work is tied to Airside D, which is currently being renovated. Airsides E and F are also part of the baggage renovation and will be renovated concurrently with the Airside D component. We are collaborating on these three together. The cross-belt sorter is being considered.

We are excited about the possibility of tying all five airsides together so a bag routed from any injection point will route across the system.

A significant goal is to create what is technically called a ‘super loop’. This would allow bags to be injected anywhere in the system and find their way to their correct destination. While this is a dream for most airports, it’s often difficult due to how airports evolve. However, Tampa is able to potentially do this, and we are excited about the possibility of tying all five airsides together so a bag routed from any injection point will route across the system. This is still in the formatting phase, but we have a vision for it.

Terminal Airside D is scheduled to open in 2028. What innovations are you trying to get into this space?

We are working hard to incorporate ‘everything’ into Airside D. A critical challenge is assessing requirements from entities like CBP (Customs and Border Protection) and considering their future technology. Given the 2028 opening date, we must carefully monitor technology trends to avoid committing to technology in 2025 that will be outdated by 2028. This requires making assumptions, for example, about what technology CBP may have.

We are looking at various things like tracking individual volumes, signage and wayfinding. A major focus is making sure we are smarter and better at things like gate utilisation, which is a big challenge for all airports. We are also considering whether the airside will be completely common-use.

How do you promote a culture of open innovation within your team and the wider business?

We are fortunate to have a supportive executive team that promotes innovation from the top down. This encourages everyone working for them to be open to innovation and collaborate. Tampa always try to find a business sponsor to champion initiatives, as innovation must solve a problem. Solving a problem for a department and having that recognised up to the executive level is our greatest measure of success. The executive team’s willingness to allow their staff community to be open to ideas and not be afraid to suggest changes is key to the culture. While it has taken time to reach this point, we are excited about where we are now, noting the receptiveness and respect among peers within the airport community.

Stay Connected with International Airport Review — Subscribe for Free!

Get exclusive access to the latest airport and aviation industry insights from International Airport Review — tailored to your interests.

✅ Expert-Led Webinars – Gain insights from global aviation leaders

✅ Weekly News & Reports – Airport innovation, thought leadership, and industry trends

✅ Exclusive Industry Insights – Discover cutting-edge technologies shaping the future of air travel

✅ International Airport Summit – Join our flagship event to network with industry leaders and explore the latest advancements

Choose the updates that matter most to you.

Sign up now to stay informed, inspired, and connected — all for free!

Thank you for being part of our aviation community. Let’s keep shaping the future of airports together!

Related topics

Baggage handling, Data, Digital transformation, Innovation, New technologies, Operational efficiency, Parking, Passenger experience and seamless travel, Terminal operations, Workforce