All-in-one equipment: risk or opportunity?

- Like

- Digg

- Del

- Tumblr

- VKontakte

- Buffer

- Love This

- Odnoklassniki

- Meneame

- Blogger

- Amazon

- Yahoo Mail

- Gmail

- AOL

- Newsvine

- HackerNews

- Evernote

- MySpace

- Mail.ru

- Viadeo

- Line

- Comments

- Yummly

- SMS

- Viber

- Telegram

- Subscribe

- Skype

- Facebook Messenger

- Kakao

- LiveJournal

- Yammer

- Edgar

- Fintel

- Mix

- Instapaper

- Copy Link

Posted: 23 February 2022 | Moventor Oy | No comments yet

Moventor Oy has built a so-called ‘all-in-one’ machine, which have been developed individually but they have also committed to develop a packet that fulfils all the needs at any airport runway inspection.

Global Reporting Format, GRF, new regulations, etc. I´m sure you have heard all about it already. Not only have we written multiple blog posts for this topic, but also Airport Council International (ACI) and International Civil Aviation Organization (ICAO) have committed to spreading the word. This information flow has also got many confused in regards to what are our needs at the airport after the new regulations including, what equipment is used, and which software is needed? Now there´s a need to fulfil all these new user requirements but can one piece of equipment do it all successfully?

Moventor – your one-time shop for safe runways

We have built one of these so-called all-in-one machines. These products have been developed individually but we have committed to providing a packet of which fulfils all the needs at any airport runway inspection. The solution is Skiddometer BV11 Vehicle Integrated, equipped with contaminant sensor and Global Runway Reporter software. The goal has always been to ensure runways are safer through the use of high quality equipment in a way which is still user friendly. Let´s look deeper in to the runway inspection needs at airports with different climate.

Operational needs

Airports around the world face challenges due to changing weather conditions such as snow, ice, and rain, and are in a need of tools to help report these conditions to the pilots. The conditions can be as such that no maintenance actions can make the runway dry, which means that according to GRF the actual conditions need to be reported.

Reporting the runway usually means inspecting the runway by driving it through. When using our Skiddometer BV11 friction tester while the visual inspection, friction is easily measured. This friction value can be correlated to Runway Condition Code from zero to six (more information about this can be provided by request) and used for total assessment of the surface conditions, especially with up- and downgrade.

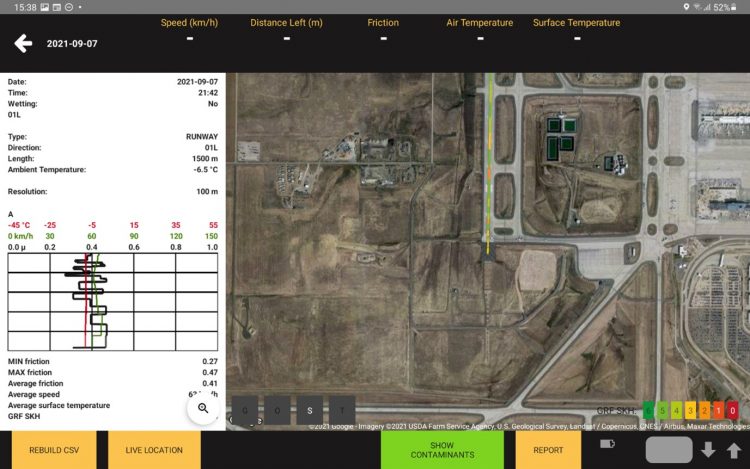

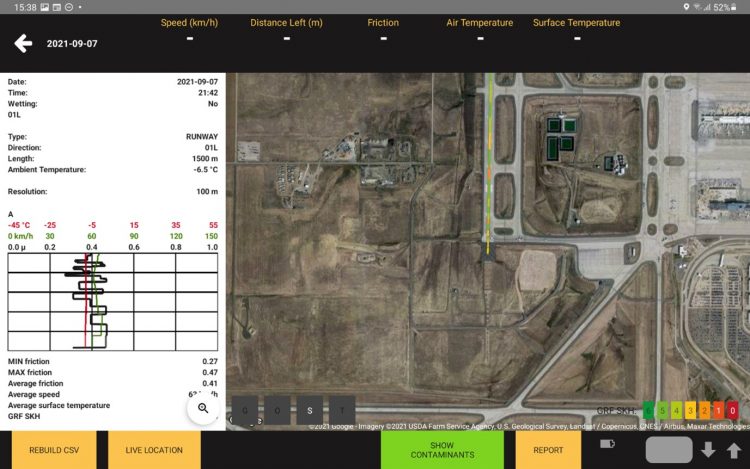

The correlation is shown in the friction graph and colour coded to the map.

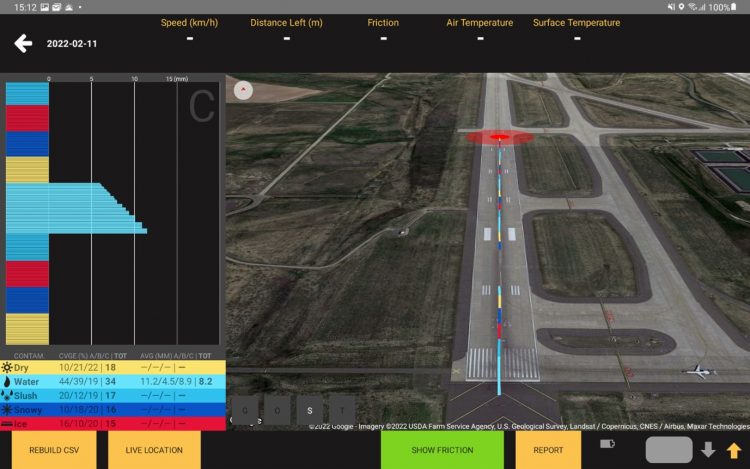

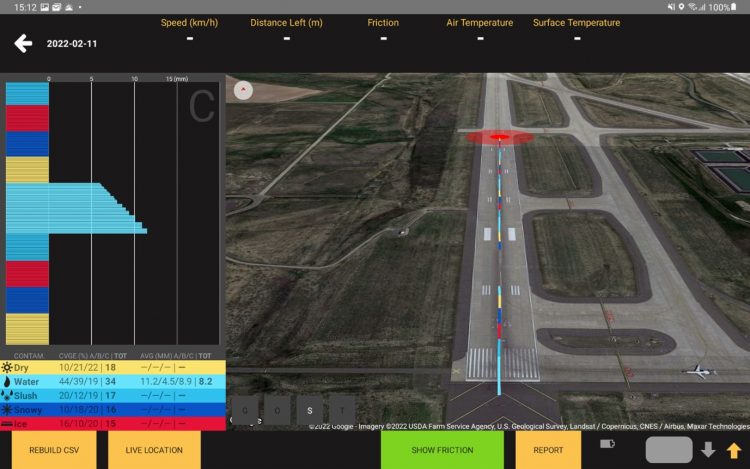

The contaminant type, coverage percentage and depth are essential part of runway reporting. This is done usually with human eye but sometimes the conditions are challenging for that. We can help the inspector to recognise the contaminant type and record a memory backup for the whole runway length. With water, we also get the depth of water film to be able to recognise the important three mm water limit for standing water. The sensor can be equipped with surface temperature and dew point information. We have set up a view which is intuitive for the inspector to see all this information.

Contaminant data is shown in graphical format and on the map with colour classification.

Now we have gathered information from the surfaces, logically the next step is to report these runway conditions. We have introduced our Global Runway Reporter software for this purpose. The software is running on the same measuring computer and by just one click you can report all necessary information. Based on our observation and measurements, we can select correct Runway Condition Code (RWYCC) for landing aircraft and correct contaminant for taking-off aircraft (more information of take-off from here).

Global Runway Reporter software in runway inspector’s vehicle.

Software is designed in a way that when sending the report from the Skiddometer BV11 vehicle, it goes directly to relevant networks, such as AFTN or AMHS. Preferably also ATIS is automatically updated based on our ATIS output. The delay is generally only seconds which increases the operational safety as the pilots gets the latest conditions immediately after the inspection. The way of handling this information flow varies country by country and we have been managing doing it for all our customers.

Maintenance needs

With maintenance, we focus on runway polishing, drainage, and rubber build-up problems. This is inspected with Skiddometer BV11 friction tester with watering system. The vehicle has everything on-board regarding wet friction testing: over 600L water tank, electrical water pump, special nozzle and computer controlling the water flow to be constant one mm at all speeds. We determine the friction levels by doing friction testing on relevant distances from the centreline. If we reach minimum limits for the friction values, we should do corrective actions as soon as possible.

Maintenance friction testing in the action with Skiddometer BV11 runway friction tester.

Meanwhile, if friction is under the minimum levels, we should use contaminant sensor to monitor if the surface is wet. In this case, if we recognise that significant portion of the runway is wet, we need to report Slippery Wet conditions from the runway. Again, we can use our Global Runway Reporter software to report these conditions and publish Runway Condition Report.

All-in-one

Considering the above, it´s safe to say that all-in-one solution in this case works perfectly. The vehicle can be used around the year regardless of the climate conditions. It fulfils all the needs to comply with GRF and help the runway inspectors challenging work. Top of all this, the vehicle model and software outputs can be selected based on your regional needs and regulations. Can it get better than this? Get yours now simply by contacting us.

To get the latest updates, remember to follow us on LinkedIn.

Related topics

Airside operations, Foreign object detection (FOD), Ground handling, Information technology (IT), Regulation and Legislation, Runways and pavements, Safety, Winter operations

Related organisations

Airport Council International (ACI), International Civil Aviation Organization (ICAO), Moventor Oy