Alstef Group’s BAGSHUTTLE provides low-bay bag storage for space optimisation

- Like

- Digg

- Del

- Tumblr

- VKontakte

- Buffer

- Love This

- Odnoklassniki

- Meneame

- Blogger

- Amazon

- Yahoo Mail

- Gmail

- AOL

- Newsvine

- HackerNews

- Evernote

- MySpace

- Mail.ru

- Viadeo

- Line

- Comments

- Yummly

- SMS

- Viber

- Telegram

- Subscribe

- Skype

- Facebook Messenger

- Kakao

- LiveJournal

- Yammer

- Edgar

- Fintel

- Mix

- Instapaper

- Copy Link

Posted: 26 August 2021 | Alstef Group | No comments yet

Passenger convenience is a major driver for airports to cater for post-check-in storage of passengers’ luggage and this service also brings many benefits to the airport.

With checked-bag storage facilities, passengers can check their bags much earlier than their normal check-in window. This means passengers can enjoy more time using the revenue-generating facilities at an airport such as shops and restaurants and similarly, allows transfer passengers the luxury of not having to collect and re-check their bags.

But checked-bag storage can also optimise the baggage handling system throughput and functionality. Having the ability to batch-build bags at make-up, alleviates make-up facility congestion and lowers peak demands, which can delay capital expenditure to increase capacity. Additionally, optimised bag make-up provides more granular sortation options such as sortation by class or transfer passengers.

Tote-based checked-bag storage options such as the Alstef Group BAGTOTE, are not an option when building height does not allow for stacker-crane-based, Automatic Storage and Retrieval Systems (ASRS), high-bay storage. Lane-based conveyor storage is a low-bay storage option that can often fit into existing buildings but can also have a large footprint.

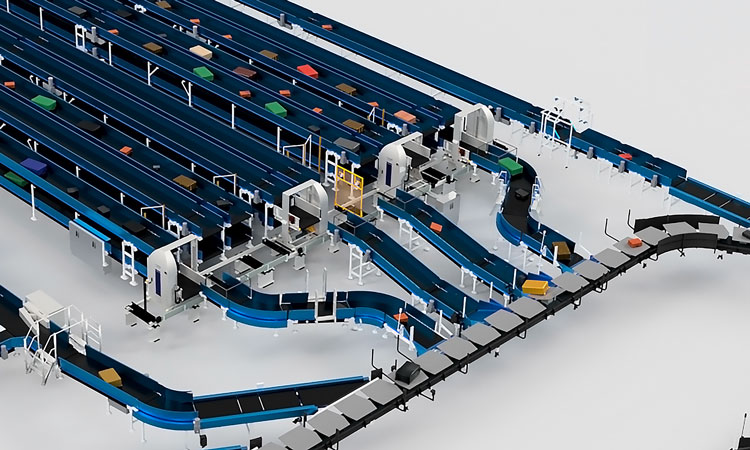

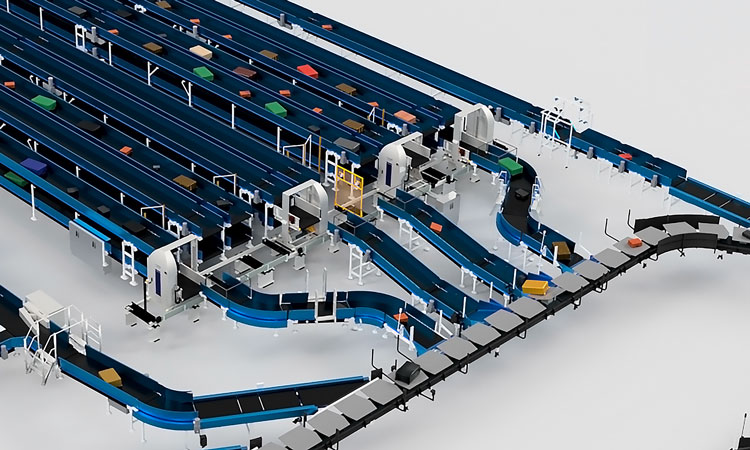

To fully optimise space efficiency, Alstef Group has designed the BAGSHUTTLE.

With checked-bag storage facilities, passengers can check their bags much earlier than their normal check-in window. This means passengers can enjoy more time using the revenue-generating facilities at an airport such as shops and restaurants and similarly, allows transfer passengers the luxury of not having to collect and re-check their bags.

But checked-bag storage can also optimise the baggage handling system throughput and functionality. Having the ability to batch-build bags at make-up, alleviates make-up facility congestion and lowers peak demands, which can delay capital expenditure to increase capacity. Additionally, optimised bag make-up provides more granular sortation options such as sortation by class or transfer passengers.

Tote-based checked-bag storage options such as the Alstef Group BAGTOTE, are not an option when building height does not allow for stacker-crane-based, Automatic Storage and Retrieval Systems (ASRS), high-bay storage. Lane-based conveyor storage is a low-bay storage option that can often fit into existing buildings but can also have a large footprint.

To fully optimise space efficiency, Alstef Group has designed the BAGSHUTTLE.

BAGSHUTTLE is a fully configurable, high-speed shuttle storage system that distributes bags to conveyor-based low-storage bays within a minimal footprint. A BAGSHUTTLE system comprises shuttle conveyors that quickly and efficiently transfer bags to batch-storage lanes or partial-flight, flush storage lanes. BAGSHUTTLE comes in single, double or triple-layer configurations to really make the most of the available space and each BAGSHUTTLE unit can run at up to 350 storage cycles per hour, per shuttle, depending on the configuration (number of lanes/layers, position of loading point).

“Originally developed for Istanbul Ataturk Airport, we recently installed BAGSHUTTLE at Sheremetyevo Airport in Moscow as it was ideally suited to their limited space requirements,” says Philippe Hamon, Sales Director – Airport Solutions. “Using a mix of single and two-layer shuttle systems, we were able to fit 60 lanes of storage into a very small space and the total capacity of the solution allows for storage of 4,000 bags. The system can be filled to capacity in less than two hours and can fully unload in less than one hour,” adds Philippe.

The airport can now offer greater convenience to its passengers with the added benefit of optimising its bag make-up processes. The high-speed responsiveness of the BAGSHUTTLE system means the airport can reduce the opening time of the make-up chutes/carousels increasing the overall make-up capacity.

About Alstef Group

Alstef Group designs, integrates and supports automated turnkey solutions for the airport, intralogistics and healthcare markets. The group provides its customers with agile and innovative solutions to meet their present and future needs with its four business units: Alstef, BA Systèmes, BA Healthcare and Glidepath.

Across more than 10 countries and with installed systems on all five continents, Alstef Group has around 850 employees and generated revenue of €140 million in 2020.

Issue

Related topics

Baggage handling, New technologies, Passenger experience and seamless travel

Related airports

Istanbul Atatürk Airport, Moscow Sheremetyevo International Airport (SVO)