Deicing at Denver International Airport

- Like

- Digg

- Del

- Tumblr

- VKontakte

- Buffer

- Love This

- Odnoklassniki

- Meneame

- Blogger

- Amazon

- Yahoo Mail

- Gmail

- AOL

- Newsvine

- HackerNews

- Evernote

- MySpace

- Mail.ru

- Viadeo

- Line

- Comments

- Yummly

- SMS

- Viber

- Telegram

- Subscribe

- Skype

- Facebook Messenger

- Kakao

- LiveJournal

- Yammer

- Edgar

- Fintel

- Mix

- Instapaper

- Copy Link

Posted: 7 February 2009 | Keith D. Pass, Environmental Programme Administrator, Denver International Airport | No comments yet

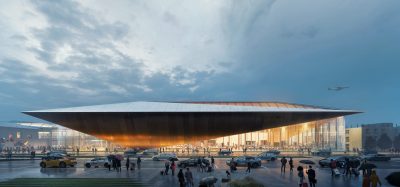

As the newest major international hub airport in the United States, Denver International Airport (DEN) has benefitted from its planners’ foresight in acquiring enough land (53 square miles) to allow ample room for future growth. When developing both the airport’s design and layout, DEN’s planners also made sure to incorporate the lessons learned at Denver’s previous airport, Stapleton International. One of the main areas of focus was ensuring that the new ‘mile high’ airport would have concentrated deicing operations near runways, so that DEN could contain spent aircraft deicing fluid (ADF) and also maintain safe and efficient aircraft traffic flow. Efforts made at the design stage have allowed Denver International Airport to become one of the earliest proponents and practitioners of environmentally friendly aircraft deicing.

As the newest major international hub airport in the United States, Denver International Airport (DEN) has benefitted from its planners’ foresight in acquiring enough land (53 square miles) to allow ample room for future growth. When developing both the airport’s design and layout, DEN’s planners also made sure to incorporate the lessons learned at Denver’s previous airport, Stapleton International. One of the main areas of focus was ensuring that the new ‘mile high’ airport would have concentrated deicing operations near runways, so that DEN could contain spent aircraft deicing fluid (ADF) and also maintain safe and efficient aircraft traffic flow. Efforts made at the design stage have allowed Denver International Airport to become one of the earliest proponents and practitioners of environmentally friendly aircraft deicing.

Beginning in the winter of 1987 and continuing until Stapleton closed in 1995, Continental Airlines conducted one of the country’s earliest pilot tests for the recycling of glycol from spent ADF. In addition to environmental benefits, this pilot test proved the economic and operational feasibility of recycling spent ADF. With these lessons in mind, DEN was designed and constructed with a ‘flow through’ air traffic pattern. In the most commonly used configuration, inbound flights land on parallel north-south runways on the airport’s east side and taxi to concourse gates in the middle of the airfield. In deicing conditions, departing flights taxi from the gates to dedicated deice pads near parallel north-south outbound runways, located on the west airfield. Two additional runways, which are oriented east and west, were designed and built for each side of the airport for a total of six runways. DEN owns enough land to allow for a total of 12 runways at full airport build-out.

DEN was built incorporating state-of-the-art construction and with environmental protection in mind. Dedicated deice pads were constructed to the west of each of the three concourses. Since the airport opened in 1995, passenger and traffic growth has made it necessary to add two more west-airfield deice pads. A sixth deice pad is located at DEN’s cargo facility, south of the passenger terminal. Full aircraft deicing is permitted only on the dedicated deicing pads, although limited deicing is permitted at the concourse gates. Propylene glycol is the only authorised ADF used at DEN. Each deice pad has an in-ground drainage system that collects and conveys spent ADF and stormwater runoff to storage tanks or lined retention ponds, depending on the runoff’s glycol concentration. Runoff with a concentration of greater than one-percent glycol is conveyed to storage tanks located at an onsite glycol recycling facility. Runoff from limited gate deicing is typically less than one-percent glycol and is therefore conveyed to the lined retention ponds for subsequent discharge to the local publicly-owned water treatment works under a contribution permit. DEN’s storage infrastructure for the spent ADF and associated stormwater runoff includes a total capacity of 61.6 million gallons in lined retention ponds and 3.32 million gallons in above-ground storage tanks.

The onsite glycol recycling facility mentioned above is one of the few on-site, or more specifically ‘on-airfield’, glycol recycling operations in the United States. Since 2004, operation of the recycling facility has been under contract to Inland Technologies International Ltd. of Truro, Nova Scotia. Inland’s recycling process involves an initial concentration step using mechanical vapour recompression (MVR) units to achieve a concentration of approximately 50-percent propylene glycol. At present, a total of six MVRs are in operation and have a combined throughput of 24,000 gallons per day. The concentrate is then processed through vacuum distillation to approximately 99-percent propylene glycol. Using activated carbon filtration and deionisation vessels, Inland polishes the recovered product to 99 plus-percent purity and sells the product to off-site buyers as industrial grade propylene glycol.

DEN’s deicing season typically occurs between October and April, with occasional weather events in September and May. During the previous four deicing seasons, airlines have applied an average of 898,834 gallons of ADF (both Type I and Type IV ADFs) at DEN. This four-year period includes a record-setting year, the 2006-2007 deicing season, in which 1,851,460 gallons of ADF were applied (the highest one-season total since DEN’s opening). DEN’s ADF collection, conveyance, storage, and recycling systems have proven themselves with an average collection rate of 69 percent of the total ADF applied per deicing season, reportedly one of the best collection rates of any US airport. During this same four-year period, of the 69 percent of ADF collected, DEN has reclaimed an average of 66 percent and turned it into a marketable product.

A 100 percent collection rate is not achievable because some ADF will drip off an aircraft as it taxis between the deicing pad and runway, and some ADF is formulated to adhere to the aircraft until it is safely airborne. Some ADF is also carried outside the collection area by windborne mist, and aircraft and other vehicular traffic tires pick up ADF and track it off the deice pad.

Collection of the data used to calculate and document the volumes of ADF applied, collected, and recycled, is facilitated by the airport’s automated ADF distribution system. The onsite glycol facility blends virgin propylene glycol with a supplier’s additive pack to produce Type I ADF. The undiluted Type I ADF is then transferred into centralised supply tanks and distributed via an underground pipeline to loading stations at three of the west-airfield deicing pads. Type IV ADF is delivered to the airfield ready to use and is offloaded directly into tanks at the deice pads. The ADF is metered when the product is pulled from the system and is electronically recorded by an inventory management system. The airport’s ADF distribution system is used by deicing contractors and airlines that self-deice, but DEN does not perform any aircraft deicing. The fluid supplier is chosen by the airlines that use the ADF distribution system.

Increasing the volumes and efficiencies of ADF collection and recycling at DEN is a continuing goal. Compliance with federal, state, and local rules and regulations will remain a priority in the design and construction of future airport expansion projects involving a deicing component.

DEN’s environmental achievements / awards

- Environmental Management System (EMS). DEN was the first commercial service airport in the United States to receive ISO 14001 certification for the entire facility (53 square miles). Our EMS certification was achieved in 2004, and was recertified to the new 2004 standard in 2007.

- DEN was the first airport in the United States to be included in EPA’s National Performance Track Program (2006).

- In 2004, DEN was included in the Colorado Department of Public Health and Environment’s Environmental Leadership Program.

- DEN received the Metro Gold Award in 2007 for 100-percent compliance for wastewater management.

- DEN received the FAA Environmental Stewardship Award in 2008.

- DEN is participating in the GRI aviation sector supplement development for sustainability reporting for airports, togethher with other major international hubs worldwide.