Lighting the way for the future of airfield ground lighting

- Like

- Digg

- Del

- Tumblr

- VKontakte

- Buffer

- Love This

- Odnoklassniki

- Meneame

- Blogger

- Amazon

- Yahoo Mail

- Gmail

- AOL

- Newsvine

- HackerNews

- Evernote

- MySpace

- Mail.ru

- Viadeo

- Line

- Comments

- Yummly

- SMS

- Viber

- Telegram

- Subscribe

- Skype

- Facebook Messenger

- Kakao

- LiveJournal

- Yammer

- Edgar

- Fintel

- Mix

- Instapaper

- Copy Link

Posted: 2 November 2018 | Amen Tong, Dr. Nick Lau | 1 comment

Hong Kong International Airport has revolutionised the airfield ground light inspection system with the world’s first automated integrity checking system. Amen Tong, General Manager, Technical Services of the Airport Authority Hong Kong and Dr. Nick Lau, co-inventor of AGLSIS, discuss the system’s performance and impact, and their visions on utilising the cutting-edge technology to boost airport maintenance.

Hong Kong International Airport (HKIA) is one of the world’s leading and busiest airports and has always been at the forefront of technological innovation to ensure travellers enjoy the best experience in an efficient, smooth and safe manner. The airport’s latest innovation, the patented airfield ground lighting scanning and inspection system (AGLSIS), maintains HKIA’s runway lights to ensure efficiency is optimised at all times.

In 2017, HKIA broke its records again by handling 72.9 million passengers and 5.05 million tonnes of cargo and airmail. This was a remarkable achievement for an airport that only has two runways, with a flight departing or arriving every minute. The 12,700 airfield ground lights (AGLs) are one of the many components that support the airport’s round-the-clock operation, providing visual navigation to aircraft. They require constant monitoring to ensure they reach the requirements of the International Civil Aviation Organisation (ICAO). Before the invention of AGLSIS, the AGLs were visually inspected by the airport’s professional maintenance team.

Like many other busy hubs, HKIA only allows for a few hours for runway maintenance every day. At midnight each day, one of the runways is closed for inspection and maintenance until dawn. This window has recently been further squeezed as HKIA has increased take offs and landings during odd hours, posing a challenge to the maintenance team which, in turn, has led to the innovation of a smart solution.

HKIA worked with D2V, a local start-up company, and developed a new automated system that can inspect all AGLs on the 3.8km-long runway in unprecedented detail within a 15-minute period. “HKIA is striving to increase operational efficiency and is devoted to becoming a smart airport,” Amen Tong, General Manager, Technical Services of the AAHK, explains. “Back in 2016, when we learned about high-throughput scanning and processing technology, we immediately began to assess the possibility of using a more efficient way to inspect AGLs.”

AGLSIS can carry out in-depth airfield inspection in as little as 15 minutes

The system is comprised of an advanced high-throughput scanning machine which is installed on a vehicle as well as a remote computer server. The vehicle carries out an integrity inspection of the AGL at a speed of 50km/h. Everything from the bolt tightness, the number of cracks on the epoxy surrounding the AGL, to the inset light and adapter ring, is scheduled via the automated system which has increased accuracy. The solution allows maintenance teams to efficiently detect any damage to the light fittings.

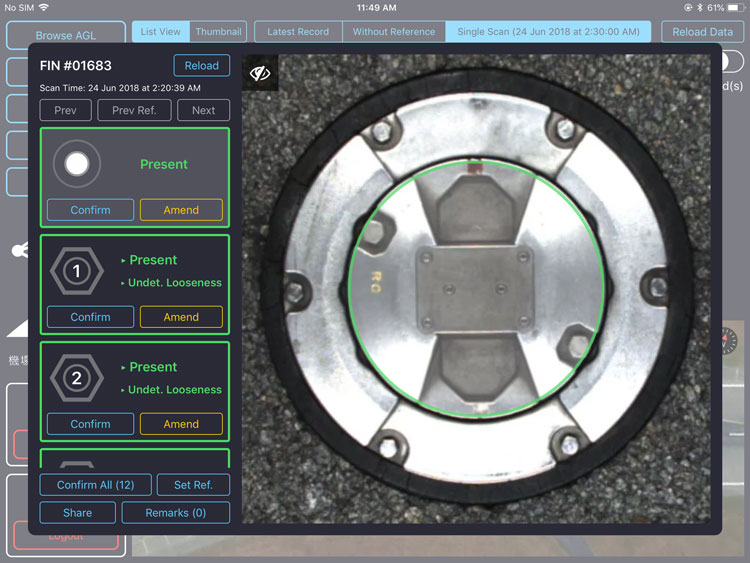

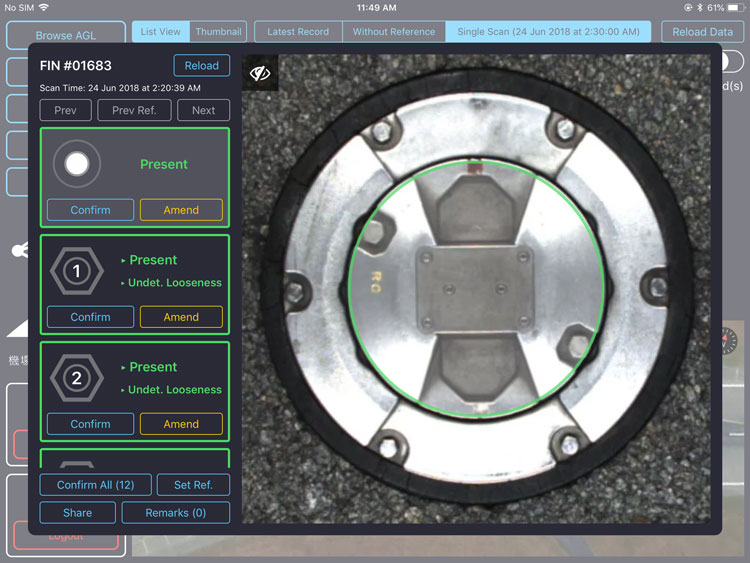

Once the frontline personnel have scanned the AGL, maintenance personnel and airport management keep track of the results of the scan through a mobile app. The maintenance team follow in a second vehicle that is equipped with the necessary tools and parts to repair any damaged lights.

The current and previous inspection results can be reviewed in detail on the mobile device application. This workflow allows technical personnel to carry out concurrent, in-depth follow-ups on AGL, which optimises inspection and repair of AGLs while keeping the whole team on the same page at the same time.

Enhancing inspection efficiency

During the year-long evaluation in the proof-of-concept phase, the system proved to be highly accurate and reliable. Moreover, if an object has an unusual appearance or even a false negative condition, the system is able to detect such ambiguity and prompt for further verification and inspection by a qualified individual who can amend any problems identified. When this new system is compared to the previous manual inspection, which can take over 90 minutes to complete the inspection on runway centerline AGLs, AGLSIS can complete this inspection in 15 minutes, which is an 83 per cent improvement in efficiency. The system has proved that it can overcome various surface conditions on AGLs whilst also combatting wide variety of weather situations.

“The highly accurate inspection results help boost the efficiency of runway inspection, while its high throughput capability addresses the ever-increasing demands to accommodate more flight movements, which in turn helps handle more passengers and more cargo,” Amen said.

The inspection results display, which can be reviewed on mobile devices

AGLSIS is now under a full implementation project at HKIA. The new system extends to support not just the runway centre-line, but also lead-on/off lights, threshold lights and touchdown zone lights.

Dr. Nick Lau, co-inventor of AGLSIS, commented: “The system leverages techniques in big data processing and machine learning for the fully automated high-throughput AGL integrity checking. Before the invention of the system, there was no easy way to inspect more than 12,000 units of airfield ground lights in such detail and in such a short period of time. It demonstrates how the technical expertise can fundamentally revolutionise an important sector of airport maintenance and development.”

Award-winning innovation

AGLSIS provides the airport with a world-leading system that makes the best use of airport maintenance windows. Furthermore, the system is so efficient that it can be used to fix AGLs in between two flights, if need be.

The groundbreaking AGLSIS technology has already been recognised by the industry, after it won the inaugural International Airport Review Award for Airside Operations in 2017, along with the Hong Kong Institution of Engineers Electronics Project competition.

Looking to the future, HKIA will continue to pioneer the use of cutting-edge technologies to improve the operation of the airport which will provide an unrivalled customer experience.

Biography

enhancement works. Amen is a Chartered Surveyor and Chartered Builder with more than 30 years of experience, within which 20 years are on the planning, design, construction, operation and maintenance of airport infrastructure, facilities and systems.

Issue

Related topics

Airfield lighting, Maintenance, Runways and pavements, Terminal operations

It says it takes 15min to check AGL but it does not say how much time you need without this system. I wonder how much time you can save with the new technology.