Is the burst of the AFFF bubble a precursor to long term environmental liabilities?

- Like

- Digg

- Del

- Tumblr

- VKontakte

- Buffer

- Love This

- Odnoklassniki

- Meneame

- Blogger

- Amazon

- Yahoo Mail

- Gmail

- AOL

- Newsvine

- HackerNews

- Evernote

- MySpace

- Mail.ru

- Viadeo

- Line

- Comments

- Yummly

- SMS

- Viber

- Telegram

- Subscribe

- Skype

- Facebook Messenger

- Kakao

- LiveJournal

- Yammer

- Edgar

- Fintel

- Mix

- Instapaper

- Copy Link

Posted: 29 July 2019 | Ian Ross Ph.D. Arcadis | 6 comments

Ian Ross from Arcadis explains how the use of new generation Fluorine Free foams are not only playing a key part in aviation fire extinguishment, but also helping to mitigate the widespread environmental concerns surrounding PFASs.

As the global drinking water crisis focused on per- and polyfluoroalkyl substances (PFASs) continues to unfold1, the ongoing use of aqueous film forming foams (AFFF) – that contain these chemicals – by the civil aviation sector is under significant scrutiny.

PFASs are extremely persistent environmental contaminants, described as ‘forever chemicals’2, which can be mobile, bioaccumulative and toxic3, potentially posing increasingly significant very long-term environmental concerns. The increasing detection of PFAS in drinking water above very low regulatory thresholds informed by the available toxicological research, suggests that PFASs are “one of the most seminal public health challenge for the next decades” according to Patrick Breysse, Director of the U.S. Center for Disease Control’s National Centre for Environmental Health4.

The environmental concerns regarding PFASs are evolving fast, but so too has been the development and optimisation of Fluorine Free Firefighting (F3) foams, which are now demonstrating comparable performance to AFFF5, 6, especially considering fire extinguishment scenarios and objectives in the aviation sector.

It is now possible to both protect the public when we consider fire safety, whilst ensuring the long-term safety of drinking-water resources and the food chain. From a holistic perspective fires can be safely extinguished without the need for fluorosurfactants (PFASs) that are present in all AFFF formulations.

Many airports globally have gained significant confidence in the fire extinguishment performance of F3 foams such they have transitioned away from AFFF containing PFASs over the last decades. For example, some major international airports using F3 foams include London Heathrow, Gatwick, Stansted and City, Manchester, Paris Charles De Gaulle, Paris Orly, Lyon, Helsinki, Lisbon, Dubai, Brussels, Copenhagen, Oslo, Stockholm, Stuttgart, Dortmund, Sydney, Melbourne and Brisbane.

Transitioning to the new generation F3 foams is a positive step towards mitigating concerns regarding PFASs as environmental regulations progress to address this class of several thousand emerging contaminants.

This article aims to provide an overview of concerns raised by scientists and environmental regulators, regarding PFASs, describe recent innovations in the development of fire-fighting foams, along with evolving engineering solutions to create stable foam blankets for superior extinguishment performance. International regulatory developments that apply to civil aviation extinguishment scenarios, as opposed to military specifications, are outlined with recent regulatory changes that allow airports to use F3 foams highlighted.

The evolution of a new generation of F3 foams that offer comparable extinguishment performance to AFFF, coupled with engineering developments to create superior stable foam blankets alongside rapidly changing regulations, allowing the use of F3 foams, provides the opportunity for their widespread adoption. Considering the accelerating pace of concerns regarding PFASs, media attention 7, 8, 9 and political focus 10 the opportunity to mitigate future environmental liabilities by avoiding use of AFFF appears to be a very wise decision.

What are PFASs?

Per- and polyfluoroalkyl substances (PFASs) are a large group of emerging contaminants that have been used in a wide array of commercial goods and products since the 1940s11. PFASs tend to be thermally stable and can repel oils and water with impressive surface tension levelling properties. Some PFASs, also termed as fluorosurfactants, have been the key ingredient in “film forming” and fluoroprotein based Class B fire-fighting foams used to extinguish liquid hydrocarbon fires. AFFF was developed in the mid-1960s and this foam in particular has been used at airports for incident response, repeated fire training events in sprinkler-based fire-suppressant systems in aircraft hangars and aviation hydraulic fluids12, 13.

PFASs include many thousands of individual compounds each with their own acronyms, which can initially be very confusing. This articles attempts to highlight the acronyms of importance considering fire-fighting foams and provide a brief overview of the importance of a few differing PFASs.

Generally, the prior regulatory focus has been on perfluorooctane sulphonic acid (PFOS) and perfluorooctanoic acid (PFOA), termed C8 or “long chain” PFASs, but there are potentially hundreds of extremely persistent fluorosurfactant PFASs in fire-fighting foams including AFFF, fluoroprotein foams (FP) and film forming fluoroprotein foams (FFFP).

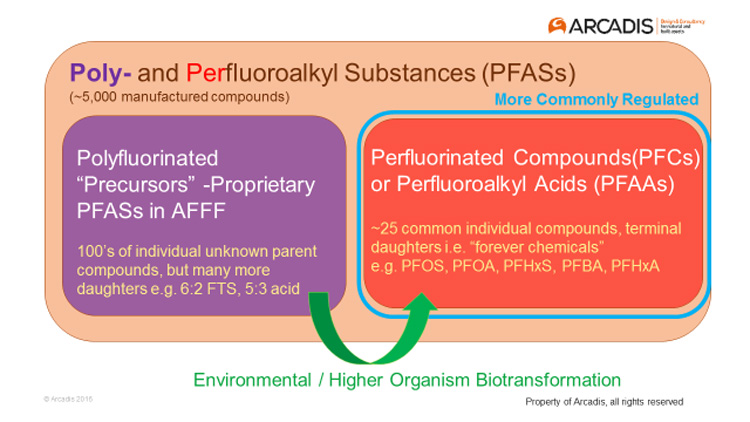

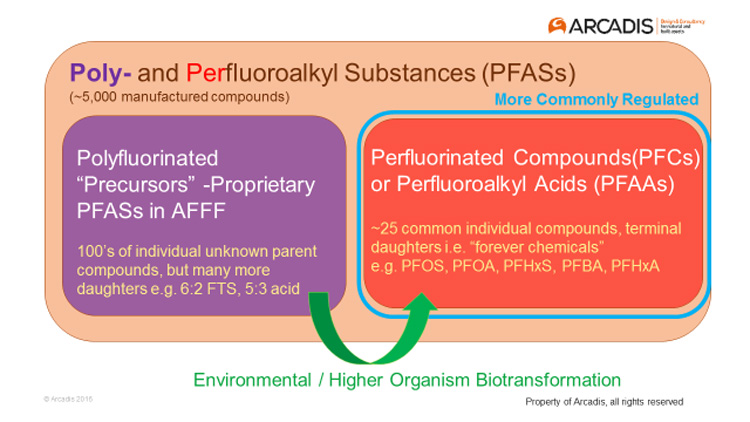

None of the thousands of PFASs are biodegradable. However the polyfluorinated PFASs, often termed “precursors”, can transform in the environment to create the perfluorinated PFASs, collectively termed perfluoroalkyl acids (PFAAs), as shown in Figure 1. The PFAAs, which include PFOS and PFOA, are the compounds generally subject to environmental regulations as opposed to their precursors. The polyfluorinated PFAA precursors in AFFF products still used today are termed fluorotelomers and are usually proprietary molecules, so they cannot be easily identified by chemical analysis and regulated as their structural formula remains confidential 14.

Figure 1. Regulated PFASs and their precursors in fire-fighting foams

Why is there a problem?

Globally, environmental regulations, focused on the PFAAs are rapidly being proposed to very conservative (low) levels, and have been evolving since 2002. Environmental concerns considering PFASs were initiated in 2000, when it was announced that the “long chain” (C8) molecule perfluorooctane sulphonic acid (PFOS) would be withdrawn from sale 15, 16.

It took until 2009 before PFOS production and uses were restricted by an international treaty, termed the Stockholm Convention on Persistent Organic Pollutants (POPs) which classed PFOS as persistent, bioaccumulative (retained within organisms) and toxic 17. The Stockholm Convention listed PFOA, as a POP, in 2019 18, 19 with a PFAS called perfluorohexanesulphonic acid (PFHxS) also currently under consideration.

As PFASs show no sign of biodegradation at all they have been described as “forever chemicals” meaning they are now permanently in the environment20. PFASs are generally water soluble and hence very mobile in the environment meaning they can be transported with groundwater well beyond the original location where they were lost to ground, termed a source area. This behaviour means they can impact immense volumes of groundwater usually referred to as large plumes. Depending on the airport’s site setting (i.e. the topography, geology, hydrology and hydrogeology), coupled with the location of drinking water supply wells, crop spray irrigation, surface waters and business using this water, PFASs may then pose a risk3, 21.

The “long chain” PFASs, including PFOS, PFOA and PFHxS bioaccumulate (concentrate) in humans, especially through consumption of PFAS impacted drinking water22, 23. Replacement fluorotelomer PFASs are “short chain” (often termed C6), they are generally more soluble in water and therefore mobile in the environment. Our understanding of the toxicology and bioaccumulation potential of the C6 PFASs is evolving. A particular concern is that C6 PFASs form a host of differing transformation intermediates, some of which are suspected to bioaccumulate24, 25 and there have been reports of increased toxicity displayed by the bioactive transformation intermediates of fluorotelomers26, 27, making them a potentially larger environmental threat.

Biodegradable F3 foams, used in training, pose negligible environmental hazards as they detoxify naturally in soils

It was noted that the Stockholm Convention Persistent Organic Pollutants Review Committee recently recommended “not to replace fire-fighting foam that contained or may contain PFOA, its salts and PFOA-related compounds with short-chain per- and polyfluoroalkyl substances (PFASs) due to their persistency and mobility as well as potential negative environmental, human health and socioeconomic impacts” 28.

Given growing evidence of human health risks and potential ecological harm, many jurisdictions are now regulating an increasing number of PFASs including both long and short chain varieties and their precursors3. While the short chain precursors are still commonly used as commercial replacements (e.g. in “C6-pure” fire-fighting foams). Many short-chain (C4-C7) PFASs, introduced as replacements for C8, have also captured the attention of environmental regulators, with short-chain PFASs regulated in Sweden, Denmark, Germany, Italy, Belgium, Switzerland, Canada and 12 U.S. states. A limited number of the PFAA precursors are now themselves regulated, such as in Sweden, Germany, Denmark, Canada and Switzerland.

There has been a dramatically accelerating focus on PFASs by environmental regulators in the last five years. For example, in 2016, the detection of PFASs in drinking water in the U.S., combined with the U.S. Environmental Protection Agency (US EPA) issuing a long-term health advisory level of 70 ng/L (for combination of PFOS and/or PFOA)29, led to 6.5 million people’s drinking water being considered unsafe30. During 2019 an increasing number of drinking water supplies have been affected by PFAS in the U.S.31, 32, with other businesses such as dairy farms also impacted33.

The regulatory trend is to consider an increasing number of individual PFASs and apply increasingly lower target concentrations. Since 2016, the drinking water guidelines have fallen sharply, to ever lower targets, with New Jersey finalising maximum concentration levels (MCLs) for PFOS at 13 ng/L and proposing a 14 ng/L target for PFOA34. These levels were also adopted by the State of California35, with the State of New York finalising MCLs of 10 ng/L for PFOS and PFOA36 37. Vermont has applied a standard of 20 ng/L to a combination of five PFAAs38, whilst New Hampshire recently announced targets of 12 ng/L for PFOA and 15 ng/L for PFOS39, Michigan announced a 16 ng/L health based value for PFOS and eight ng/L for PFOA40. Lower levels are being proposed by Denmark, with a temporary level of three ng/L for PFOS being considered. There are concerns that these very low levels are potentially higher than some detections in major rivers, such as the 238 ng/L of PFOS reported in the river Severn in the UK 41.

What PFASs are in fire-fighting foams?

The sale of firefighting foams containing PFOS ceased in 200342, but many AFFFs marketed as “short chain” (C6) fire-fighting foams still contained PFOA (C8) and it’s precursors43. In 2004 it was reported that AFFF was not a likely source of PFOA44, but subsequent analysis of C6 based foams revealed that approximately 20 per cent of the PFASs present were PFOA precursors, with the remainder being precursors to short chain PFAAs45-47. As a result of the EPA PFOA stewardship programme between 2006 and 201548, the amount of PFOA in foams was diminished to achieve a maximum of 50 mg/kg in C6-pure foams by 201549.

Chemical Analysis

There are many more proprietary PFASs present in fire-fighting foam than are regulated. These polyfluorinated precursors evade detection by common analytical methods but in the environment will be transformed to the increasingly regulated perfluorinated PFASs. Fire-fighting foams, comprise hundreds of individual PFASs which have not been accounted for until recent analytical advances have enabled the total amount of PFASs to be measured using a novel technology termed the total oxidiseable precursor (TOP) assay46, 50. In the environment, these polyfluorinated PFASs will all slowly transform to create PFAAs, such as PFOS and PFOA. Recognising this regulators in Australia have recently adopted this advanced analytical tool for sampling environmental matrices and compliance. The TOP assay is widely available commercially and may be considered best practice for assessment of PFASs in fire-fighting foams21, 51. However, recent analytical guidance in the U.S. from the Fire Fighting Foam Coalition (FFFC) recommends use of standard analyses52 to assess PFASs in fire-fighting foam concentrates, such that the vast majority of PFASs in the fluorotelomer based fire-fighting foams would not be detected21, 53.

Evolution of fire-fighting technologies

Environmental and public health concerns, regarding PFASs, developing since 2000, has stimulated significant innovation to create F3 foams, meaning that over the last 20 years, fire-fighting foams and their delivery systems have evolved to be far more effective, without a need for PFASs in most circumstances56, 54. The first F3 foams were successfully tested at large scale in 200232, with evolving improvements in performance.

AFFF is essentially a technology developed in the 1960s55 , that has now been replaced in many airports, with more modern next-generation F3 foams.

Whilst PFAS manufacturers turned to C6 PFASs with diminishing C8 content as replacements for PFOS-containing foams57, foam manufacturers such as Solberg, National Foam / Angus, Dr Sthamer, Bio-Ex, Novacool, Fomtech, Auxquimia, 3F, Chemguard, Aberdeen Foam, FireRein, FireFreeze Worldwide, Orchidee Fire, Pyrocool Technologies, Verde Environmental Inc, Tyco, VS Focum and FoamFatale have all formulated F3 Foams. As F3 foams are now accredited to the highest performance levels in International Civil Aviation Organization (ICAO) tests (Level C) and are widely available as viable replacements to AFFF, many major international and provincial airports have already transitioned to F3 foams58, 59.

There has also been significant progress made evaluating alternative engineering methods to make and propel foams. Compressed Air Foam (CAFs), which can effectively propel F3 foam to create a stable bubble blanket for rapid effective fire extinguishment, are increasingly in use in Airport Rescue Fire Fighting Vehicles (ARFFV)56, 60. Not new to foam fire-fighting, CAF has been in existence for many decades going back to the 1930s when it was first used to fight fuel fires on ships during wars in Europe. Today CAFs are more developed with engineered systems designed to provide an appropriate solution for flammable liquid fire hazards of many descriptions.

In fire tests CAFs have shown the ability to raise the performance level of any foam product as the art of optimising bubble structure can be critical to their performance. The foam produced by a good quality CAF generator consists of homogeneous micro bubbles with superior extinguishment efficiency and performance. In 2018 a CAFs foam successfully flowed approximately 40m over a burning fuel surface at the Dallas Fort Worth Airport Foam Summit61. This is 10m greater than National Fire Protection Association (NFPA) standards suggest should be applied as the maximum flow distance, yet CAF did so at half the application rate of conventional aspirated foam – two litres per minute per square metre (L/min/m2) versus four L/min/m2 for conventional aspiration.

Recent quotes for a tote of an F3 foam was US $3,917, whereas a tote of AFFF was US$5,870 and with CAFS systems typically requiring around a third of the amount of foam needed by conventional foam application equipment, there are also some major cost savings associated with switching away from AFFF to F3 foams and CAFs, with the high price associated with PFAS based foams highlighted in 200562.

Environmental management of fire-fighting foams

To assist with ensuring that all brands of F3 foams do not pose a future environmental hazard it is suggested that foam suppliers confirm that all organic components of the foams, irrespective of concentration can be confirmed to be readily biodegradable as per Organization for Economic Cooperation and Development (OECD) guidelines63. They should also confirm that there are no carcinogenic, mutagenic and reprotoxic substances (CMR) in the F3 foam formulations to help ensure the safety of the foams to firefighters. Consideration of the very comprehensive Queensland Department of Heritage and Environmental Guidance Policy regarding Firefighting Foams64, 65, could help guide policy in many jurisdictions.

Regulatory changes considering fire extinguishment

Barriers remained to the adoption of F3 foams in North American airports until recently. On 3 October 2018, the FAA Reauthorization Act of 2018 (HR 302) passed the senate66. It directs the U.S. Federal Aviation Administration (FAA) that within two year of the date of the Acts’ enactment, to “not require the use of fluorinated chemicals” to meet the prior performance standards67. This means that there will no longer be a requirement to use PFASs and thus AFFF to meet military performance standards (via the U.S. Department of Defense Military Specification MIL-PRF-24385F(SH) (MILSpec)) at civil, certified Part 139 airports across the U.S. with the MILSpec standard written around the characteristics of AFFF.

On 21 June 2019, Transport Canada published an exemption from paragraph 323.08(1)(a) of the Aircraft Fire Fighting at Airport and Aerodromes Standards, which stated “this exemption would allow Canadian airport operators to elect to transition to a fluorine-free foam which is more environmentally friendly and which currently available on the market and used in other countries” and “the Canadian airport operator shall select a fluorine-free foam with a low environmental impact (i.e. persistency, toxicity and bioaccumulative) that does not contain any fluorinated compounds such as fluorine, per-and polyfluoroalkyl substances (PFAS) or other groups of fluorinated substances such as fluorosurfactants, fluoropolymers or organofluorines.”68. Meaning Canadian airports can now transition to F3 foam.

Royal Danish Airforce in action, after adopting F3 foams

Use of tests that are appropriate to fire scenarios

Protecting human health and safety through effective fire suppression is the foremost priority of most fire-fighting foam system, although some are solely aimed at asset protection. However, a balance between minimising the environmental impact, liabilities and the long-term harm to human health caused by use of PFASs in fire-fighting foams needs to be considered to manage the overall risk of fire protection.

The ICAO testing regime is specifically designed for civil aviation fire extinguishment scenarios and not those encountered by the military. Therefore, it provides a detailed and tailored series of tests and specifications for extinguishment of the fuels used in bulk by civil aviation for appropriate life protection69. Jet-A (aviation kerosene) is the preferred fuel in ICAO tests as it is the fuel used in bulk quantities by civil aviation. The extinguishment scenario for which the ICAO test is built around is to secure the critical area around an entrance/egress point for passengers to self-evacuate or for firefighters to enter the fuselage to effect a rescue. The ICAO fire test therefore accurately reflects a civilian airport’s fire-fighting and rescue regime.

MILSpec testing objectives are fire scenarios faced by military organisations and the hazards they pose, considering bulk use of gasoline and the presence of live munitions. The rationale for the MILSpec requirements has been described by the Naval Research Laboratory as an “attempt to provide the best flammable liquid firefighting agent for military applications”70. As civil aviation fires are not in military settings the use of ICAO tests are more appropriate.

There are also other aspects of the fire tests to consider. The ICAO test simulates an ARFFV drawing up to the critical area and discharging its water/foam to primarily control and ultimately extinguish the fire. In the 2013 revision, movement of the nozzle was stopped, therefore simulating a stationary ARFFV as they can be very difficult to reposition during an emergency especially whilst they are discharging their fire-fighting media. Each of the MILSpec fire tests is carried out by an experienced operator, where the hand-held nozzle is used to ‘actively’ fight the fire. This simulates a human intervention to the fire scenario and not a stationary ARFFV.

Successful large scale tests using F3 foams at DFW airport in October 2018

Recent independent foam testing

The industry group LASTFIRE which is funded on a non-profit basis by fuel storage companies, develops best practice guidance for storage tank protection, free from commercial bias from foam manufacturers71. LASTFIRE has carried out a very extensive series of tests using “new generation” foams of both C6 and F3 types. These tests were aimed specifically at storage tank related scenarios but have relevance to all foam applications including the aviation industry. They have involved a range of incident scenarios including tank fires, dike area fires and general spill fires as well as standard test protocols such as EN1568 and LASTFIRE. The LASTFIRE standard test protocol was developed, initially by Mobil Research and Development Corporation but finalised by LASTFIRE, specifically to evaluate foam performance for the critical application of tank fires – an example of a test simulating a specific application, as all performance-based tests should be for critical situations. The work of LASTFIRE is ongoing but the most recent large-scale tests involved 40x7m spill fires with JetA and were carried out in cooperation with DFW airport Research and Training facility.

LASTFIRE are keen to emphasise that the research is ongoing and further tests are planned. Conclusions regarding foam performance should not be generic, as there are both good and bad examples of each foam category on the market. The results show that F3 Foams can successfully extinguish both spill and tank fires using standard application rates – and indeed at more critical application rates too, given the correct application techniques and foam quality. Application techniques tested have included both forceful (monitor) and gentle (pourer) conventional proprietary aspirating and “non-aspirating” devices. An interesting part of the work is testing of alternative application methods including CAF and Self Expanding Foam. In the DFW test for example, the 40m long test pan with Jet A fuel was efficiently and effectively extinguished using a CAF foam pourer at 50 per cent of the application rate of a conventional aspirating foam pourer. Comparative testing with conventional foams was carried out on tank scenarios as part of the overall series.

LASTFIRE have also developed a ”best practice” covering assurance protocol involving all stages of foam procurement, application, management and ultimately disposal. Again, this is aimed specifically at storage tank application but the principles and most of the detail is applicable to all foam application including aviation. The work of LASTFIRE is complemented by that of the Etank Project carried out by RISE in Stockholm which included the use of F3 foam on water soluble fuels.

In the Oil and Gas sector, Equinor (formerly Statoil) are responsible for about 50 per cent of total production in the North Sea totalling some 2.5 million barrels a day, with comments regarding use of F3 foams from Lars Ystanes at Equinor that “we regard the new fluorine-free foam as a fully acceptable and even better replacement for AFFF”72. Other oil companies have transitioned to F3 foams for some applications and are committed to doing so completely when further testing is completed

Experiences with F3 foams

The successful use of F3 foams to effectively manage multiple aircraft fires at major airports has is being increasingly reported73, 74. In 2019, more successful reports of use of F3 foams are being highlighted, with safe evacuation of all 80 passengers and crew from an A319 engine fire on landing in 2013, then in 2016 all 282 passengers and crew were safely evacuated after a Boeing 777 fire. In 2018 a chemical factory fire in Melbourne was successfully extinguished using only F3 foams75.

Feedback regarding the performance of F3 foams from Graeme Day (London Heathrow Airports Fire Service Compliance Manager), following successful transition of F3 foams at Heathrow Airport76, were that F3 foam has “no operational problems and performs perfectly in an ARFF setting”, with “environmental impact and consequential remediation and clean-up costs of using a fluorine-free foam compared to AFFF, FFFP, or FP are effectively zero and firewater runoff can be discharged directly to ground or drainage systems”.

Graeme continued “Since purchasing our fluorine free foam, we have used it on two separate aircraft fires (an A321 and a 787) and it worked perfectly. Furthermore, the clean-up costs from these incidents were zero as following tests of the fire ground water runoff by the UK Environment Agency and local water company, we were given permission to wash the foam solution into Heathrow’s surface water drainage system. This meant that the affected runways were available for use very quickly which had obvious financial benefits for Heathrow. We were not allowed to do this when we used AFFF and following the 2008 777 incident we spent thousands of pounds and many months disposing of the fire ground runoff. Another benefit of being able to wash fluorine free foam solution into the surface water drainage system is that our crews can train with foam concentrate instead of water or training foam.”

The Royal Danish Airforce has been using F3 foams for several years, with an ethos of “Train as you Fight”, as the Danish Airforce trains with the same firefighting foams and fuels as encountered in real life incidents77, with their confidence extinguishing fires using F3 foams evident as a result78-80, with comments from Lars Andersen the Fire-Chief that “my experience is that fluorine free foam works flawlessly”81. Following recent testing exercises with F3 foams Lars stated “put you self in the place of a crew member trapped in a fuselage engulfed in flames. Ask yourself a question; would I trust the fluorine free foam? I would”82, 83.

Considering use of F3 foams with CAFs, Kim Olsen, Head of Copenhagen Airport Rescue & Firefighting Academy, Copenhagen Airport stated “CAFs has a tremendous capacity for knocking down the fire compared to the normal aspirated nozzles. The CNPP results showed that CAFs is some 40 per cent more efficient! Moreover, test results also showed that the new fluorine –free foam was just as efficient as AFFF!”56. Kim Olsen also noted that “in 2014 work on environmental clean-up, containment and re-construction of the Fire Training area was started. This was a huge project and Copenhagen Airports A/S invested more than €15 million in this project”72, indicating the magnitude of costs that can be associated with environmental clean-up of AFFF.

Groundwater sampling for PFASs at an airport

Remediation

Remediation of PFASs in soil, ground and surface waters poses some unique challenges. However cost effective pragmatic and ingenious approaches are evolving84. Treatment of short chain PFASs poses a greater challenge than their long chain predecessors, as they can be much more water soluble and mobile. Water treatment technologies, such as granular activated carbon, typically struggles to remove them21.

Large scale remediation of a proprietary C6 foam spill in Australia in 2017, seems to be an example of the future potential liabilities associated with holding and using C6 foams85. Regulatory compliance requested measuring of PFASs using TOP assay, making the remediation significantly more challenging. The cleanup technology used is shown below and represents the first use of an ozofractionation system to comprehensively treat 20,000 cubic metres (m3) of PFASs impacted wastewater, as determined using TOP assay.

Ozofractionation used to treat more than 20,000 m3 of PFAS-impacted wastewater

Foam transition

Foam transitions assists with managing liabilities whilst moving to sustainable alternatives86. Successful foam transition takes a well-developed, site-specific strategy prepared by a qualified team of fire engineers, environmental engineers/scientists, technology providers, equipment specialists and operations contractors16. Some of the considerations associated with foam transition include:

- Maintaining compliance with fire protection regulations and insurance accreditation

- Development of a performance-based detailed foam procurement specification with appropriate acceptance testing

- Implement the transition whilst maintaining a functional fire suppression system to protect human health and assets

- A good understanding of the design basis of the fire protection system and operational knowledge of existing equipment

- Compatibility assessment of system components with new foam

- Effective decontamination of existing equipment in contact with foam to prevent cross-contamination of new foam

- Proper planning for containment and disposal of waste generated during transition

- Effective secondary containment, and inspection and maintenance procedures are required.

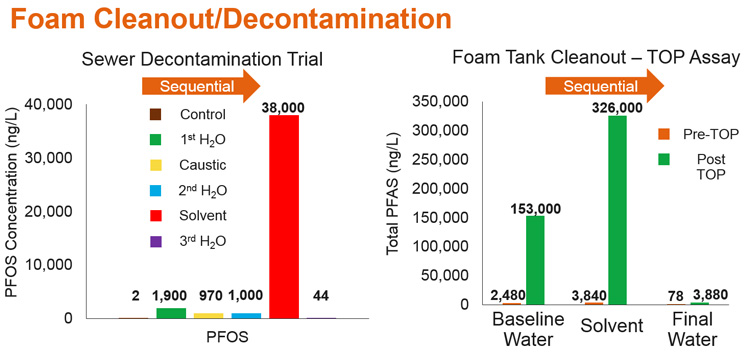

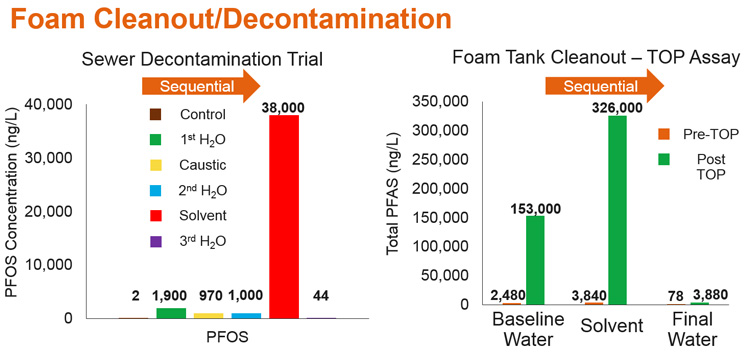

Effective decontamination of infrastructure is essential if cross contamination of the new F3 foam with residual PFASs is to be avoided. Failure to undertake appropriate decontamination may lead to future liabilities if appropriate cleanout of equipment is not conducted. Biodegradable, non-toxic solvents have been developed and applied to prevent rebound and effectively extract PFASs from equipment, because rinsing using only water has been shown to be ineffective (Figure 2.)

Figure 2: Data from a foam transition decontamination case study in Australia indicating the effectiveness of a biodegradable solvent for PFAS mass removal compared to water or caustic washes

There are on-going challenges associated with managing PFASs including potential legacy management of C8 and C6 contamination of soil, groundwater and concrete surfaces, whilst ongoing use of C6 represent a source of future contamination. There is evidence that some fire training areas can remain a source of C8 PFASs for at least 20 years87, 88 following their last use and that the surface of concrete can continue leaching PFASs for decades89.

There are many evolving solutions to manage PFASs releases to the environment, such as concrete surface treatments, soil stabilisation and technologies using ultrasound which can destroy PFASs, via a process termed sonolysis, creating innocuous fluoride90. Mobile sonolysis units to destroy PFASs in fire-fighting foam concentrates are currently being developed for commercial use, which will significantly reduce the costs of foam disposal.

Conclusion

The growing concerns regarding drinking water impacts from PFOS, PFOA and PFHxS, is driving a dramatically increased regulatory, media and political focus on the wider class of PFASs. At the same time the performance of F3 foams at extinguishing fires has markedly improved such that it’s performance is comparable to AFFF. So now the balance between the perceived risk of transitioning to F3 foams, versus the potential harm caused and liabilities associated with continued use of PFAS based foams, makes evaluation of how to move away from C8 and C6 PFAS based foams a wise commercial decision.

Transitioning to the new generation F3 foams is a positive step if airports have not already made this choice, as they are now effective for fire extinguishment and have negligible long term environmental hazards.

With grateful contributions from Dr. Niall Ramsden Ph.D., LASTFIRE coordinator

Airports that are using the F3 foams

Paris Charles De Gaulle

Paris Orly

London Gatwick

London Heathrow

Copenhagen

Oslo

Stockholm

Copenhangen

Dubai

Dortmund

Koln Bonn

Stuttgart

Allgau

Melbourne

Sydney

Brisbane

Canberra

Lyon

Helsinki

Lisbon

Leeds/Bradford

London City

Bristol

Guernsey

Brussels

Manchester

Stansted

East Midlands

Blackpool

Bristol

Newquay

Edinburgh

Billund

Cairns

Gold Coast

Perth

Adelaide

Hobart

Townsville

Avalon

Broome

Alice Springs

Rockhanpton

Horn Island

Launceston

Biography

Ian Ross, Ph.D., is a Senior Technical Director and Global, In Situ Remediation Technical Lead / Global PFAS Lead at Arcadis. He is focused on PFASs management for clients in Europe, America, Middle East, Asia and Australia in the Civil Aviation, Defence and Petrochemical sectors to mitigate the environmental effects following use of AFFF. As a result of this global role Ian has interfaced with firefighting experts from multiple continents. He has over 27 years’ experience considering analysis, fate, transport and remediation of xenobiotics and has been working on PFASs since 2005, using expertise considering surfactant behaviour gained in 1987. He has extensive experience of applied research and consultancy work on contaminated land projects and has commercialized innovative remedial technologies resulting in winning several national and international awards. Ian was part of the Arcadis team authoring the CONCAWE PFAS guidance document for the Oil Industry and has published several articles on PFAS analysis, site investigation and remediation, including a recent book entitled “Emerging Contaminants Handbook”.

References

- Urbi, J. A new drinking water crisis hits US military bases across the nation. 2019; Available from: https://www.cnbc.com/2019/07/12/new-drinking-water-crisis–stemming-from-us-military-bases-pfas-contamination.html.

- Kary, T. To the EPA, ‘Forever Chemicals’ Are a Big Problem Now. 2019; Available from: https://www.washingtonpost.com/business/to-the-epa-forever-chemicals-are-a-big-problem-now/2019/02/13/d9a75104-2f64-11e9-8781-763619f12cb4_story.html?utm_term=.6ee917de4992.

- Ross, I., Hurst, J., . Managing Risks and Liabilities associated with Per- and Polyfluoroalkyl Substances (PFASs). CL:AIRE Technical Bulletin TB19 2019; Available from: https://www.claire.co.uk/component/phocadownload/category/17-technical-bulletins?download=668:tb-19-managing-risks-and-liabilities-associated-with-per-and-polyfluoroalkyl-substances-pfass-2019.

- Knaus, C. Toxic firefighting chemicals ‘the most seminal public health challenge’. 2017; Available from: https://www.theguardian.com/australia-news/2017/oct/18/toxic-firefighting-chemicals-the-most-seminal-public-health-challenge.

- LASTFIRE, LARGE SCALE TEST PROGRAMME FOR STORAGE TANK FIRES PRESS RELEASE. 2017.

- Ramsden, N., Foam Testing, in Pertroleum Review. 2018, Energy Institute. p. 32-33.

- Lerner, S. THE U.S. MILITARY IS SPENDING MILLIONS TO REPLACE TOXIC FIREFIGHTING FOAM WITH TOXIC FIREFIGHTING FOAM. 2018; Available from: https://theintercept.com/2018/02/10/firefighting-foam-afff-pfos-pfoa-epa/

- Soechtig, S. THE DEVIL WE KNOW THE CHEMISTRY OF A COVER-UP. 2018; Available from: https://thedevilweknow.com/.

- Soechtig, S. The Devil We Know 2018 – The Chemistry Of A Cover Up Documentaries. 2018; Available from: https://www.youtube.com/watch?v=Zjs3hsIFCHw&t=25s.

- Warren, E. No more excuses – Granite Staters deserve real action to combat PFAS. 2019; Available from: https://www.seacoastonline.com/news/20190713/no-more-excuses–granite-staters-deserve-real-action-to-combat-pfas.

- OECD. TOWARD A NEW COMPREHENSIVE GLOBAL DATABASE OF PER- AND POLYFLUOROALKYL SUBSTANCES (PFASs). 2018; Available from: http://www.oecd.org/officialdocuments/publicdisplaydocumentpdf/?cote=ENV-JM-MONO(2018)7&doclanguage=en.

- OECD, Report 23: REPORT OF AN OECD WORKSHOP ON PERFLUOROCARBOXYLIC ACIDS (PFCAs) AND PRECURSORS. 2007, 2007.

- De Silva, A.O., et al., Detection of a cyclic perfluorinated acid, perfluoroethylcyclohexane sulfonate, in the Great Lakes of North America. Environmental Science & Technology, 2011. 45(19): p. 8060-6.

- Place, B.J. and J.A. Field, Identification of novel fluorochemicals in aqueous film-forming foams used by the US military. Environ Sci Technol, 2012. 46(13): p. 7120-7.

- EPA, U. EPA and 3M ANNOUNCE PHASE OUT OF PFOS. 2000; Available from: https://archive.epa.gov/…

- Barboza, D., E.P.A. Says It Pressed 3M for Action on Scotchgard Chemical. 2000.

- Convention, S. PFOS, its salts and PFOSF. 2009; Available from: http://chm.pops.int/Implementation/IndustrialPOPs/PFOS/Overview/tabid/5221/Default.aspx.

- Williams, D. PFOA Added to Stockholm Convention POP list. 2019; Available from: https://www.chemanager-online.com/en/news-opinions/headlines/pfoa-added-stockholm-convention-pop-list.

- Convention, S. The new POPs under the Stockholm Convention. 2019; Available from: http://chm.pops.int/TheConvention/ThePOPs/TheNewPOPs/tabid/2511/Default.aspx.

- Allen, J.G. These toxic chemicals are everywhere — even in your body. And they won’t ever go away. 2018; Available from: https://www.washingtonpost.com/opinions/these-toxic-chemicals-are-everywhere-and-they-wont-ever-go-away/2018/01/02/82e7e48a-e4ee-11e7-a65d-1ac0fd7f097e_story.html?utm_term=.50ff01264ee2.

- Ross, I., Kalve E., McDonough, J., Hurst, J., Miles, J., Pancras, T., Per- and Polyfluoroalkyl Substances, in Emerging Contaminants Handbook, M.G. Caitlin Bell, Erica Kalve, Ian Ross, John Horst, Suthan Suthersan, Editor. 2019, CRC Press: Boca Raton, FL, USA. p. 85-257.

- Authority, E.F.S., Risk to human health related to the presence of perfluorooctane sulfonic acid and perfluorooctanoic acid in food. 2018: https://www.documentcloud.org/documents/4620589-EFSA-PFOS-and-PFOA-Draft.html.

- Guelfo, J.L., et al., Evaluation and Management Strategies for Per- and Polyfluoroalkyl Substances (PFASs) in Drinking Water Aquifers: Perspectives from Impacted U.S. Northeast Communities. Environ Health Perspect, 2018. 126(6): p. 065001.

- Kabadi, S.V., et al., Internal exposure-based pharmacokinetic evaluation of potential for biopersistence of 6:2 fluorotelomer alcohol (FTOH) and its metabolites. Food Chem Toxicol, 2018. 112: p. 375-382.

- Neltner, T. The elephant in the room: potential biopersistence of short-chain PFAS. 2019; Available from: http://blogs.edf.org/health/2019/02/20/potential-biopersistence-short-chain-pfas/.

- Rand, A.A. and S.A. Mabury, Is there a human health risk associated with indirect exposure to perfluoroalkyl carboxylates (PFCAs)? Toxicology, 2017. 375: p. 28-36.

- Phillips, M.M., et al., Chronic toxicity of fluorotelomer acids to Daphnia magna and Chironomus dilutus. Environmental Toxicology and Chemistry, 2010. 29(5): p. 1123-1131.

- Pollutants, S.C.o.P.O. Recommendation by the Persistent Organic Pollutants Review Committee to list perfluorooctanoic acid (PFOA), its salts and PFOA-related compounds in Annex A to the Convention and draft text of the proposed amendment. 2019; Available from: http://chm.pops.int/….

- USEPA. Drinking Water Health Advisories for PFOA and PFOS. 2016; Available from: https://www.epa.gov/ground-water-and-drinking-water/drinking-water-health-advisories-pfoa-and-pfos.

- Hu, X.C., et al., Detection of Poly- and Perfluoroalkyl Substances (PFASs) in U.S. Drinking Water Linked to Industrial Sites, Military Fire Training Areas, and Wastewater Treatment Plants. Environmental Science & Technology Letters, 2016.

- Pascus, B. New study claims 43 states expose millions to dangerous chemical in drinking water. 2019.

- Group, E.W. Mapping the PFAS Contamination Crisis: New Data Show 610 Sites in 43 States. PFAS Contamination In the U.S. 2019; Available from: https://www.ewg.org/interactive-maps/2019_pfas_contamination/.

- Linn, A. ‘This has poisoned everything’ – pollution casts shadow over New Mexico’s booming dairy industry. 2019; Available from: https://www.theguardian.com/us-news/2019/feb/20/new-mexico-contamination-dairy-industry-pollution.

- State of New Jersey, D.o.E.P. DEPARTMENT OF ENVIRONMENTAL PROTECTION MOVING FORWARD WITH SCIENCE-BASED HEALTH STANDARDS FOR PFOA AND PFNA. Available from: http://www.nj.gov/dep/newsrel/2017/17_0104.htm.

- Board, S.W.R.C. GROUNDWATER INFORMATION SHEET Perfluorooctanoic Acid (PFOA) & Perfluorooctanesulfonic Acid (PFOS). 2018; Available from: https://www.waterboards.ca.gov/gama/docs/pfoa.pdf.

- Health, N.Y.S.D.o. Drinking Water Quality Council Recommends Nation’s Most Protective Maximum Contaminant Levels for Three Unregulated Contaminants in Drinking Water. 2019; Available from: https://www.health.ny.gov/press/releases/2018/2018-12-18_drinking_water_quality_council_recommendations.htm.

- Cuomo, A.M. Governor Cuomo Announces Availability of $350 Million for Water System Upgrades Statewide and Directs Health Department to Begin Adopting Maximum Contaminant Levels for PFOA, PFOS and 1,4-Dioxane. 2019; Available from: https://www.governor.ny.gov/news/governor-cuomo-announces-availability-350-million-water-system-upgrades-statewide-and-directs.

- Health, V.D.o. Perfluoroalkyl and Polyfluoroalkyl Substances (PFAS) in Drinking Water. 2018; Available from: http://www.healthvermont.gov/sites/default/files/documents/pdf/ENV_DW_PFAS.pdf.

- Martin, J. NHDES Submits Final Rulemaking Proposal for PFOA, PFOS, PFHxS and PFNA. 2019; Available from: https://www4.des.state.nh.us/nh-pfas-investigation/?p=1044.

- Environment, M.D.o. News Release: Michigan moves forward on PFAS in drinking water rules. 2019; Available from: https://content.govdelivery.com/accounts/MIDEQ/bulletins/24df7cf

- Loos, R., et al., EU-wide survey of polar organic persistent pollutants in European river waters. Environ Pollut, 2009. 157(2): p. 561-8.

- Santoro, M.A. Brief History of Perfluorochemical Brief History History of Perfluorochemical Perfluorochemical Production, Products and Environmental Presence. 2008; ASTSWMO Mid ASTSWMO Mid-Year Meeting:[Director Regulatory Affairs Affairs 3M Company, St. Paul, MN].

- Bagenstose, K. Dangers of firefighting foam discussed in 2001, document shows. 2017; Available from: https://www.theintell.com/news/20170609/dangers-of-firefighting-foam-discussed-in-2001-document-shows.

- Cortina, T., EPA Workgroup determines AFFF not a likely source of PFOA. Industrial Fire Journal, 2004(June): p. 14.

- Backe, W.J., T.C. Day, and J.A. Field, Zwitterionic, cationic, and anionic fluorinated chemicals in aqueous film forming foam formulations and groundwater from U.S. military bases by nonaqueous large-volume injection HPLC-MS/MS. Environ Sci Technol, 2013. 47(10): p. 5226-34.

- Houtz, E.F., et al., Persistence of perfluoroalkyl acid precursors in AFFF-impacted groundwater and soil. Environ Sci Technol, 2013. 47(15): p. 8187-95.

- D’Agostino, L.A. and S.A. Mabury, Identification of novel fluorinated surfactants in aqueous film forming foams and commercial surfactant concentrates. Environ Sci Technol, 2014. 48(1): p. 121-9.

- EPA, U. Fact Sheet: 2010/2015 PFOA Stewardship Program. 2015; Available from: https://www.epa.gov/assessing-and-managing-chemicals-under-tsca/fact-sheet-20102015-pfoa-stewardship-program.

- Mennie, C. Draft amendment to ban the use of fire-fighting foams containing perfluorinated alkylated substances (PFAS) – Consultation report. 2017.

- Houtz, E.F. and D.L. Sedlak, Oxidative conversion as a means of detecting precursors to perfluoroalkyl acids in urban runoff. Environ Sci Technol, 2012. 46(17): p. 9342-9.

- Ross, I., Houtz, E., Kalve, E., McDonough, J., Hurst, J. and Miles, JAL., PFASs and the TOP Assay. INDUSTRIAL FIRE JOURNAL, 2018. First Quarter: p. 26.

- Coalition, F.F.F. Analytical Method for Measuring PFAS in AFFF Firefighting Foam Concentrate. 2019; Available from: https://docs.wixstatic.com/ugd/331cad_4eb7dca6a804487cb21943d26f27bf34.pdf.

- Kempisty, D.M., Xing, Y., Racz, L., Perfluoroalkyl Substances in the Environment: Theory, Practice, and Innovation. 2018.

- LASTFIRE. LASTFIRE Foam Application Tests, Dallas Fort Worth Airport. 2018; Available from: http://www.lastfire.co.uk/default.aspx?ReturnUrl=%2f.

- Tuve, R.L., Jablonski, E.J. , METHOD OF EXTINGUISHING LIQUID HYDROCARBON FIRES, U.S.P. Office, Editor. 1966.

- Reisch, M.S. What is the price of fire safety? 2019; Available from: https://cen.acs.org/business/specialty-chemicals/price-fire-safety/97/i2.

- Day, G. Changing to Fluorine Free Fire Fighting Foams – A Case Study. 2017; Available from: http://www.lastfire.org.uk/uploads/Foam%20Summit/Graeme%20Day%20-%20Changing%20to%20FF%20Firefighting%20Foam%20Case%20Study.pdf.

- Day, G. A Positive Step. 2012; 3rd Quarter:[Available from: https://www.solbergfoam.com/getattachment/ff7b7829-c9a6-4dce-bc32-ff1618c25bab/A-Positive-Step.aspx.

- Olsen, K.T. CAFS & FFF in ARFF. Fire & Rescue 2012; Available from: https://www.solbergfoam.com/getattachment/b706ff4d-1f47-4030-bd7d-cc8762d3bfed/CAFS-FFF-In-ARFF.aspx.

- Firehouse. CAFS: So Effective It Changed The Rules, So We Changed The Laws. 2000; Available from: https://www.firehouse.com/home/article/10545473/cafs-so-effective-it-changed-the-rules-so-we-changed-the-laws.

- Systems, A. DFW Fire Testing. Available from: https://www.youtube.com/watch?v=uXyGlYHw_ZM&t=33s.

- Pabon, M., High Performance Firefighting Foam. Industrial Fire Journal, 2005. April: p. 20.

- OECD. OECD GUIDELINE FOR TESTING OF CHEMICALS Ready Biodegradability. 1992; Available from: https://www.oecd.org/chemicalsafety/risk-assessment/1948209.pdf.

- Queensland, S.o. Environmental Management of Firefighting Foam Policy Explanatory Notes Revision 2. 2016; Available from: https://environment.des.qld.gov.au/assets/documents/regulation/firefighting-foam-policy-notes.pdf.

- Queensland, S.o., Operational Policy – Environmental Management of Firefighting Foam 2016.

- Halsey, A. Senate gives final approval for FAA reauthorization, sends bill to White House. 2018; Available from: https://www.washingtonpost.com/transportation/2018/10/03/senate-gives-final-approval-faa-reauthorization-sends-bill-white-house/?utm_term=.dfecb901113f.

- Congress, U.S. FAA Reauthorization Act of 2018. 2018; Available from: https://docs.house.gov/billsthisweek/20180924/HR302.pdf.

- Canada, T. Exemption from paragraph 323.08(1)(a) of the Aircraft Fire Fighting at Airport and Aerodromes Standards made pursuant to section 303.08 of the Canadian Aviation Regulations. 2019; Available from: https://www.tc.gc.ca/CivilAviation/Regserv/Affairs/exemptions/docs/en/3210.htm.

- ORGANIZATION, I.C.A., Doc 9137-AN/898 Airport Services Manual Part 1 — Rescue and Firefighting Fourth Edition, 2015. 2016.

- Patricia A. Tatem, C.W., Ralph Ouellette, Robert L.Darwin and Douglas Barylski, MILITARY SPECIFICATION MIL-F-24385F FIRE EXTINGUISHING AGENT, AQUEOUS FILM FORMING FORM (AFFF) LIQUID CONCENTRATE, FOR FRESH AND SEAWATER. 2000.

- LASTFIRE. Large Atmospheric Storgae Tank Fires. Available from: http://www.lastfire.co.uk/default.aspx?ReturnUrl=%2.

- Bluteau, T., Cornelsen, M., Day, G., Holmes, N.J.C., Klein, R.A., Olsen, K.T. , McDowall, J.G., and R. Stewart, Tisbury, M. , Webb, S., Whitehead, K., Ystanes, L. THE GLOBAL PFAS PROBLEM: FLUORINE-FREE ALTERNATIVES AS SOLUTIONS FIREFIGHTING FOAMS AND OTHER SOURCES – GOING FLUORINE-FREE. IPEN 2019/Stockholm Convention COP-9 White Paper 2019; Available from: https://ipen.org/sites/default/files/documents/the_global_pfas_problem-v1_5_final_18_april.pdf.

- Allcorn, M., Bluteau, T., Corfield, J., Day, G., Cornelsen, M., Holmes, N.J.C., Klein, R.A., McDowall, and K.T. J.G. Olsen, Ramsden, N., Ross, I., Schaefer, T.H. l, Weber, R., Whitehead, K. . Fluorine-Free Firefighting Foams (3F) – Viable Alternatives to Fluorinated Aqueous Film-Forming Foams (AFFF). White Paper prepared for the IPEN by members of the IPEN F3 Panel and associates, POPRC-14, Rome 17-21 September 2018. 2018; Available from: https://ipen.org/sites/default/files/documents/IPEN_F3_Position_Paper_POPRC-14_12September2018d.pdf.

- Willson, M. ARFF and recovery: Focusing on the best fire protection. 2018 [cited 2019; Available from: https://www.internationalairportreview.com/article/79314/focusing-on-the-best-fire-protection/.

- Willson, M., Learning from Past Foam Incidents and Considerations Necessary when Changing Foams How Might We Fare Today?, in Fire Australia 2019. 2019: Melbourne.

- Allcorn, M., Bluteau, T. , Corfield, J., Day, G. , Cornelsen, M. , Holmes, N.J.C. , Klein, R.A. , McDowall, J.G., Olsen, K.T., Ramsden, N., Ross, I. , Schaefer, T.H., Weber, R., Whitehead, K. . Fluorine-Free Firefighting Foams (3F) – Viable Alternatives to Fluorinated Aqueous Film-Forming Foams (AFFF). 2018; Available from: https://ipen.org/sites/default/files/documents/IPEN_F3_Position_Paper_POPRC-14_12September2018d.pdf.

- Andersen, L. Train as you fight with Fluorine Free Foam. 2018; Available from: https://www.linkedin.com/pulse/train-you-fight-fluorine-free-foam-lars-andersen/.

- Airforce, R.D. Fluorine Free Foams Demonstrated by Airforce. 2018; Available from: https://www.youtube.com/watch?v=GUfaJ8nNTeo&t=11s.

- Airforce, R.D. Fluorine Free Foam Extinguishment by Airforce. 2018; Available from: https://www.youtube.com/watch?v=yCzPt4S3fqI&t=5s.

- Airforce, R.D. Fluorine Free Foams used to Effectively Extinguish Hydrocarbon Fires by Airforce. 2018; Available from: https://www.youtube.com/watch?v=QFuX25fPTIY.

- Andersen, L. How about fluorine free foam. Does it work in practice? 2019; Available from: https://www.linkedin.com/pulse/how-fluorine-free-foam-does-work-practice-lars-andersen/.

- High flow and fluorine free foam. Lars Andersen; Available from: https://www.linkedin.com/pulse/high-flow-fluorine-free-foam-lars-andersen/.

- Andersen, L. Drill with fluorine free foam. 2019; Available from: https://www.youtube.com/watch?v=B5HpMqKe3C4&feature=youtu.be.

- Ross, I., J. Hurst, J. Miles, E. Houtz, J. McDonough and J. Burdick, Remediation of Poly- and Perfluoro Alkyl Substances: Developing Remediation Technologies for Emerging Challenges. Proceedings of the Fourth International Symposium on Bioremediation and Sustainable Environmental Technologies, Battelle, Miami, 2017.

- Knaus, C. Firefighting foam spilled at Brisbane airport enters river and kills fish. 2017; Available from: https://www.theguardian.com/environment/2017/apr/14/firefighting-foam-spill-at-brisbane-airport-enters-river-and-kills-fish.

- Ross, I., Burdick J., . Balancing Fire Safety and Environmental Liabilities: Transitioning Firefighting Foams. 2018; Available from: https://www.arcadis.com/media/5/0/4/%7B50476C6C-90AB-4B7C-A153-16F8B58D7ED3%7DBR_PFAS%20Foam%20Transition%20Perspective_web_ZP20181012.pdf.

- Weber, A.K., et al., Geochemical and Hydrologic Factors Controlling Subsurface Transport of Poly- and Perfluoroalkyl Substances, Cape Cod, Massachusetts. Environ Sci Technol, 2017. 51(8): p. 4269-4279.

- McGuire, M.E., et al., Evidence of remediation-induced alteration of subsurface poly- and perfluoroalkyl substance distribution at a former firefighter training area. Environ Sci Technol, 2014. 48(12): p. 6644-52.

- Baduel, C., C.J. Paxman, and J.F. Mueller, Perfluoroalkyl substances in a firefighting training ground (FTG), distribution and potential future release. J Hazard Mater, 2015. 296: p. 46-53.

- Ross, I., et al., A review of emerging technologies for remediation of PFASs. Remediation Journal, 2018. 28(2): p. 101-126.

Thanks for writing this article.

If we do a root cause analysis of why we are in this position… I.e. why is this emerging contaminant and others getting into our bodies through food and water. Most RCAs on this issue will lead you to the end of the road in that regulatory processes are not developed, or are by-passed/not followed if they are developed….it’s too easy to find a loop hole. If we ask the final “why” question at this point in our RCA the answer I believe is $$$. Getting that new product out is more important so corporations can get the cash flow turned on …. this has become the priority.

We have seen this with other high visibility concerns like pesticides that are killing our pollinators and possibly creating long term food production concerns. We have also seen this more and more in drug development and use. I.e. opioids, drug and resistant bacteria.

We can do better!

Where do we stand meeting level B foam for protection of helidecks?

Thank you very much Ian for this very interesting article and especially very relevant with environmental considerations and issues.

I read it with the greatest interest.

With the development of the technology of fire and vapor control by encapsulating techniques, why this category of extinguishing agent is not studied by the ICAO?

Thank you for this information. I live in Fairbanks, Alaska and we have several airports with this contamination here and statewide as well.

Up until recently, this non-AFFF alternative was not readily acknowledged by the STATE of Alaska, Department of Transportation or our State Department of Environmental Conservation leadership.

Can you provide me with more information on the biodegradable solvent (components, etc.)for PFAS mass removal (as compared to water or caustic washes) as shown in Figure 2 of the article? I’m working on converting fire protection system to FFF from AFFF and need to clean out the underground foam piping at commercial aviation fuel storage facilities in the U.S.

Thank you very much Ian for this very interesting article and especially very relevant with environmental considerations and issues.

I read it with the greatest interest.