Keeping friction consistent

- Like

- Digg

- Del

- Tumblr

- VKontakte

- Buffer

- Love This

- Odnoklassniki

- Meneame

- Blogger

- Amazon

- Yahoo Mail

- Gmail

- AOL

- Newsvine

- HackerNews

- Evernote

- MySpace

- Mail.ru

- Viadeo

- Line

- Comments

- Yummly

- SMS

- Viber

- Telegram

- Subscribe

- Skype

- Facebook Messenger

- Kakao

- LiveJournal

- Yammer

- Edgar

- Fintel

- Mix

- Instapaper

- Copy Link

Posted: 26 January 2011 | Frank Holt, ASTM International Committee Member | No comments yet

ASTM International is one of the largest voluntary standards development organisations in the world-a trusted source for technical standards for materials, products, systems, and services. Known for their high technical quality and market relevancy, ASTM International standards have an important role in the information infrastructure that guides design, manufacturing and trade in the global economy.

ASTM Committee E17 on Vehicle-Pavement Systems formed in 1960 to bring together many of the worlds experts in friction and develop standards for data collection, equipment design and data analysis. In December 2010 E17 celebrated its 50th anniversary at its meeting in New Orleans. The Committee celebration was attended by one of the founders of the original committee, Mr. William Goodwin, who served as a Chairman of E17 and also as Chairman of ASTM.

ASTM International is one of the largest voluntary standards development organisations in the world-a trusted source for technical standards for materials, products, systems, and services. Known for their high technical quality and market relevancy, ASTM International standards have an important role in the information infrastructure that guides design, manufacturing and trade in the global economy.

ASTM Committee E17 on Vehicle-Pavement Systems formed in 1960 to bring together many of the worlds experts in friction and develop standards for data collection, equipment design and data analysis. In December 2010 E17 celebrated its 50th anniversary at its meeting in New Orleans. The Committee celebration was attended by one of the founders of the original committee, Mr. William Goodwin, who served as a Chairman of E17 and also as Chairman of ASTM.

ASTM is a trusted source for technical standards for materials, products and systems within the global transport industry. The Committee, with a current membership of approximately 170 has 11 technical subcommittees which has a jurisdiction of over 40 standards. The society recently held its annual Friction Workshop where one of the focuses was on friction testers from airports around the world.

The Workshop held at the Penn State Thomas D. Larson Pennsylvania Transportation Institute in September 2010, addressed two of the important issues which are critical to bringing together worldwide friction testers used at airports so that friction data can be compared between devices. Those issues included in this year’s work included water nozzle flow and distribution as well as tyre wear-in. Attendees covered a cross section of equipment manufacturers, academics and users.

During the three day event, the equipment tested the multiple surface types and textures at the track. The evaluation of water distribution was part of the ASTM effort to bring more standardization to friction measuring equipment. ASTM standard E2340 requires the water to be applied to the test surface just ahead of the test tyre, so as to provide the chosen nominal water film thickness across the full width of the test tyre at any test speed.

Thanks to Dr. Zoltan Rado from Penn State, a design for a basic water distribution checking device was made and a prototype manufactured. The intent of the organizers is to develop a portable device and procedure that all manufacturers and users could use to verify water distribution and volume.

Some might ask why this is important in the measurement of friction. Friction measurements used to determine the timing of rubber removal need to be accurate and repeatable. The application of water to contaminate the surface is a critical influence on the Mu levels obtained.

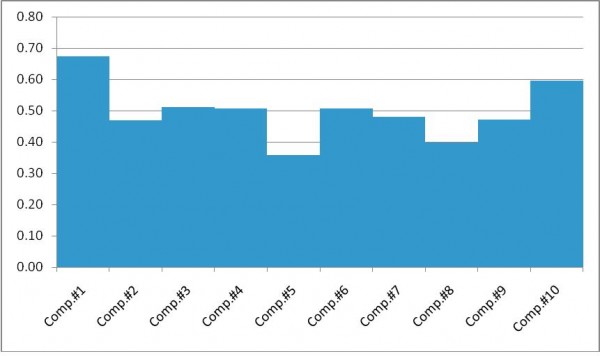

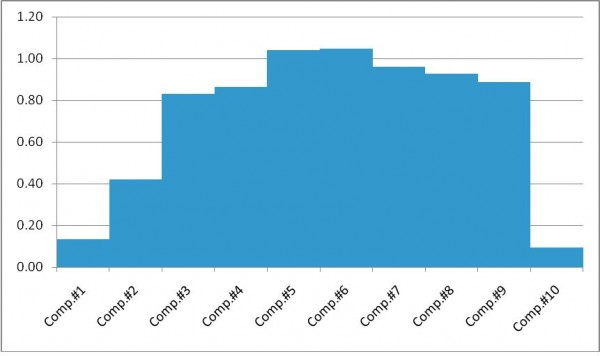

Dr. Rado developed a procedure to determine the volume of water in each of the sections of the distribution box and then predict the water film thickness, and as shown in Figure 1 the results indicate a reasonably even distribution of water across the area of the tyre footprint.

Figure 1Water film thickness, in mm, calculated for each of the chambers across the distribution box. Note that the E274 device specifies 0.5mm water film thickness.

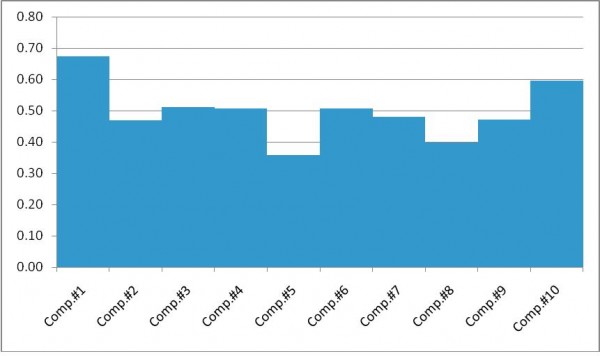

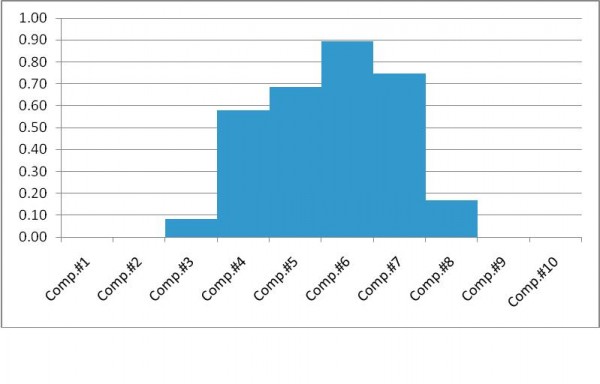

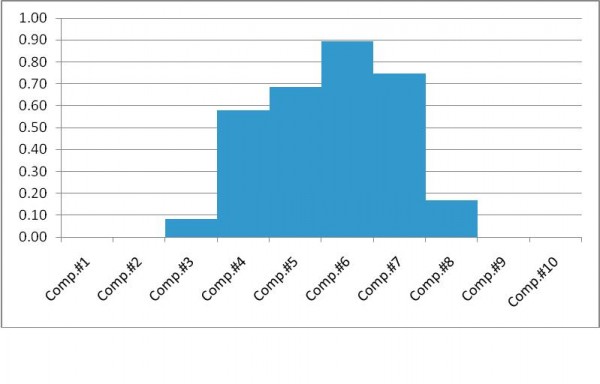

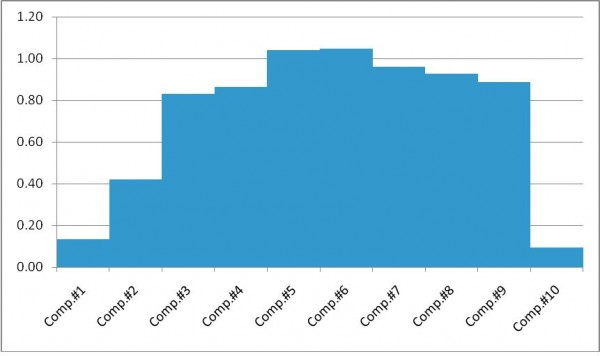

Subsequently a number of the fixed slip devices were tested to see how their nozzles distributed water. This is shown in Figure 2 and Figure 3.

Figure 2 Target water film thickness for each device was 1.0 mm across the ASTM E1551 tyre width

As can be seen, these two CFME provide different results in distribution and thickness, which will result in differing Mu values. Further analysis and a modification of the test procedure will provide additional work for the 2011 Workshop. One can say, as a result of the 2010 work effort, that there is a difference in nozzle design, size, shape and flow. Making a standard nozzle design and flow with matching distribution will help provide better correlation between friction devices, and improved capability when comparing Mu values between devices.

Figure 3Water nozzle distribution

The second objective of the workshop was to verify the wear in period on ASTM Test tyres. This task was performed by two locked wheel testers equipped with E501 test tires. The E501 test tyre is made from the same compound as the E1551 test tyre used on the majority of the CFME devices in the world. It should also be noted that the E1844 Test tyre is also manufactured with the same tyre compound. The manufacturer donated tyres for the testing and provided a representative on site to verify the condition of the specimens at various points in the testing. Durometer readings were taken during the program and noted for future reference.

The preliminary results of the study showed that the current 200 mile (320km) wear-in period for the E501 tyre is important as there is some variation to the friction data during early measurements. Wear-in on the E1551 tyres, tested during 2009 and the 2010 workshop, indicated that roughly 2 miles (32km) of wear-in provide consistent Mu measurements.

It is anticipated that further work on water distribution and nozzle shape and size will continue in 2011 and results will provide additional specifications to be included in ASTM E2340 and will ultimately bring the CFME devices closer together in performance. Further results and details from the 2010 workshop will likely be distributed as they opportunity presents itself. The participation of the equipment manufacturers and users continues to provide a unique opportunity to benefit airports around the world.

Other actions included discussions on the development of standards for calibration sites including locations, texture requirements and ranges for pavement surfaces at the sites. This work effort is considered critical to the correlation of devices and will hopefully address not only pavement types and configurations but also try to address the need for both winter and summer calibration capability. Efforts to advance this calibration site definition in an ASTM Standard form are approaching completion with a standard expected in 2011.

About the Author

Mr. Holt is Senior Vice President for Business Development with Dynatest International A/S. He is a graduate of York University in Toronto, Canada. He has spent more than 35 years in the non-destructive evaluation of pavements and bridges, including friction, roughness, condition, and bearing capacity. He has worked with more than 700 airports worldwide, performing pavement management evaluations and assisting airport authorities to determine their pavement management needs. Mr. Holt is an active member of TRB Committee AFD10 Pavement Management and AFD90 Surface Properties-Vehicle Interaction. Mr. Holt is currently the Chairman of ASTM Committee E17 Vehicle Pavement Systems.