Does new Fluorine Free firefighting foam MilSpec deliver equivalent life-saving performance under increasingly severe climatic conditions?

- Like

- Digg

- Del

- Tumblr

- VKontakte

- Buffer

- Love This

- Odnoklassniki

- Meneame

- Blogger

- Amazon

- Yahoo Mail

- Gmail

- AOL

- Newsvine

- HackerNews

- Evernote

- MySpace

- Mail.ru

- Viadeo

- Line

- Comments

- Yummly

- SMS

- Viber

- Telegram

- Subscribe

- Skype

- Facebook Messenger

- Kakao

- LiveJournal

- Yammer

- Edgar

- Fintel

- Mix

- Instapaper

- Copy Link

Posted: 22 March 2024 | Mike Willson | No comments yet

For International Airport Review’s Issue 4 2023 Mike Willson, a firefighting foam and foam systems specialist investigates whether a new F3 MilSpec for land-based freshwater aviation-use applications is functional enough to keep passengers safe.

Most readers appreciate regulations are tightening around fluorinated foams and there is a growing diversity of fluorine free foam (F3) alternatives available. A new U.S. Military Specification (MilSpec)1 has recently been released for qualifying F3 for land-based freshwater aviation-use applications, but does it deliver the levels of functionality necessary to keep our travelling public safe?

How does this F3 testing compare with existing AFFF MilSpec2 and ICAO (International Civil Aviation Organisation) fire tests3 at Levels B and C? Are we encouraging weaker foam agents potentially delivering slower fire control, longer extinguishment, and quicker escalation risks when composite materials off-gas toxic and flammable vapours inside the cabin within 30-40 seconds4, which could significantly reduce passenger safety? All at a time when realistic live-fire training is harder to achieve, temperatures are rising, frequency of incidents like runway incursions and near-miss flight experiences are increasing. All represent important safety considerations needing to be faced during fire emergencies. So is this new F3 fire test1 ‘future-proofed’? More specifically, will it provide equivalent safety under increasingly demanding and hot conditions being witnessed as temperatures continue rising like this northern summer?

Last eight years were ‘hottest on record’

Unprecedented temperature records have been broken across the northern hemisphere during 2022-23. Temperatures exceeding 40oC experienced at London’s Heathrow Airport5, Paris; Rome; Madrid; Athens; Tehran; Delhi; Bangkok; Beijing; Dallas etc. The New York Times confirmed in January 20236 “The last eight years were the hottest on record”.

It is also forecast to become hotter more frequently, bringing significant changes for continuing passenger safety. The adverse heat stress, potential loss of life and environmental impacts that may result from heated fuselages, increased smoke, re-involvement from smouldering composites, excessive firewater runoff, extended foam use (even if non-fluorinated), plus disruption and danger to other aircraft, passengers, flight crews and firefighters, should not be under-estimated in major aircraft fire incidents, even if rarely occurring.

Aircraft take-off performance decreases in high temperatures

Already elevated temperatures show decreased aircraft take-off performance. 2023 research7 found “it is urgent and crucial to understand the effects of increasing temperature on the complicated and comprehensive performances of aircraft. As air warms, it becomes less dense. Low-density air conditions further lead to reduced lifts for aircrafts, which significantly influences the maximum take-off weight (MTOW) of an aircraft. The warming air leads to the MTOW reducing and take-off distance increasing.” It is also found that “the take-off distance does not change linearly with temperature but shows a stronger increase with higher temperature.” Extended take-off distances and reduced aircraft manoeuvrability during landing, increase risk of over-runs and unexpected accidents under such challenging temperature conditions.

Foam cooling effects reduced in hot summers

Hot summers will significantly reduce the dramatic cooling effect relied upon by foams at ‘room temperature (20oC)’ established by U.S. Naval Research Laboratory (NRL) in 20158, finding “as a result of the large temperature gradient between the foam and fuel layers, heat conducts very quickly from the fuel to the foam, which reduces the surface temperature of the fuel.” These findings were validated by NRL 20179 testing, confirming “measurements show that the fuel temperature near the foam-fuel interface (~1mm deep) decreases from about 85°C to less than 60°C in less than 10s. … We propose that the very fast and significant vapor pressure reduction caused by cooling with foam could contribute strongly to suppression of pool fires by rapidly decreasing the fuel evaporation rate. The rapid effect of surface cooling could play an important role in knockdown of the flames in the initial stages of fighting a pool fire. However, the surface cooling mechanism alone will not completely extinguish a flame because it will not suppress evaporation enough to prevent the formation of a combustible fuel-air mixture. Flame extinction is impacted by other mechanisms, such as fuel transport through the foam, which would be reduced by surface cooling of the fuel. Reduced fuel transport through foam tends to enhance flame extinction.” Hot summers would dramatically reduce this substantial cooling effect, thereby making the fire harder and slower to control and extinguish, with increasing risk of re-ignition.

Smouldering composite materials risk re-ignition

Research by the U.S. Federal Aviation Administration (FAA) in 201210 found composite material smouldering was difficult to extinguish, exacerbating problems of unpredictable, sudden and sustained re-ignition during survivor evacuations, especially if delayed by elderly, disabled, parents with frightened children, injured individuals, potentially risking many lives.

Europe’s 2014 Cordis Project4 also found composite burn though times never exceeded 15 minutes of the FAA test “Composites are an efficient fire barrier, but:

- The resin warming destroys the cohesion between carbon fibres, which changes the mechanical properties of the composite. A mechanical stress can break the fibres as soon as the first layers of fibres are de-correlated;

- The fast heat penetration in the composite induces an off-gassing of pyrolysis products, potentially toxic (intoxication of the occupants) and flammable (gas ignition) with a potential fire propagation in the cabin after few tens of seconds.” potentially having a fatal effect on passengers and crew survivability.

Also, “an excess of fuel from the pyrolysis of the [composites] fuselage skin, and this situation induces an increase in the [ignited] thermal plume volume.” …increasing danger potentially for firefighters and evacuating passengers outside the aircraft, until all fire is rapidly extinguished with re-involvement prevented.

Consideration should also be given to Fluorine Free Foams (F3s) without fuel repelling and vapour sealing additives11-15, being more vulnerable to these serious problems. Yet NFPA 403 Aviation Rescue and Fire Fighting (ARFF) Services Standard16 has extended response times from two to three minutes, despite ICAO Level B and C requiring extinguishment within two minutes under cool 15oC conditions, and smoke build-up in fuselages potentially being lethal after three to four minutes10, or potentially igniting within one minute4 where fire impacts composites. Could we be under-estimating life safety protections under challenging summer operating conditions? Particularly when relying on less demanding fire approval testing like the new F3 MilSpec1 (more equivalent to ICAO Level B3, but with important extra testing requirements).

NFPA 403 recommends 7.5L/min/m2 (0.18gpm/ft2) application rate for ICAO Level B

NFPA 403:2018 (Annex B.6)16 explains: “There has been limited full-scale testing of ICAO C foams, but tests to date have reflected extinguishments on Jet A within 1 minute at ICAO Application rates of 0.992 gpm/ft2 (3.75L/min/m2). The 0.13gpm/ft2 (5.5L/min/m2) application rate requirement for AFFF meeting MilSpec in NFPA 403 is 40% higher.”

AFFF MilSpec uses a 330% safety factor on its fire test application rate to cover unexpected challenges when fire strikes, but still keeping people safe. Could this very low 40% Level C safety factor be effective, even during hot summers? Is Level B’s safety factor with 1 minute Jet A extinguishment even less? Might we be seriously eroding passenger safety?

NFPA 403 recommends increasing Level B ARFF application rates above 5.5L/min/m2 widely used by major airports currently. Annex B.616 continues: “Airports adopting ICAO foam concentrates should evaluate equipment requirements any time a switch to a new manufacturer of foam concentrates is considered. Therefore, starting with 2018 edition of NFPA 403, the following application rates by test standard are used:

(1) Mil-F 24385 and ICAO Level C = 0.13gpm/ft2 or 5.5L/min/m2

(2) ICAO Level B = 0.18gpm/ft2 or 7.5L/min/m2

(3) ICAO Level A = 0.20gpm/ft2 or 8.2L/min/m2”

Presumably this recommended higher Level B rate also applies to the new F3 MilSpec using equivalent Level B fire test density?

Important additional tests absent from ICAO

ICAO has no mechanism in its fire test protocol3 to check lean foam induction, dry chemical compatibility, realistic 5:1 expansion nozzle capability, nor verifying firefighting foam functionality under challenging temperatures of 40oC or above, being increasingly experienced across continents. It’s a once only, single new foam (pre-mixed) fire test conducted at 15oC to gain ICAO certification – valid for ever; not the nine or 10 fire tests required for MilSpec1,2 qualification with five-yearly repeat testing. Is that good enough? Does it verify fitness for purpose? Especially when plane loads of passengers’ lives may be reliant on a single fire test, with possibly older and weaker agent effectiveness under increasingly severe conditions.

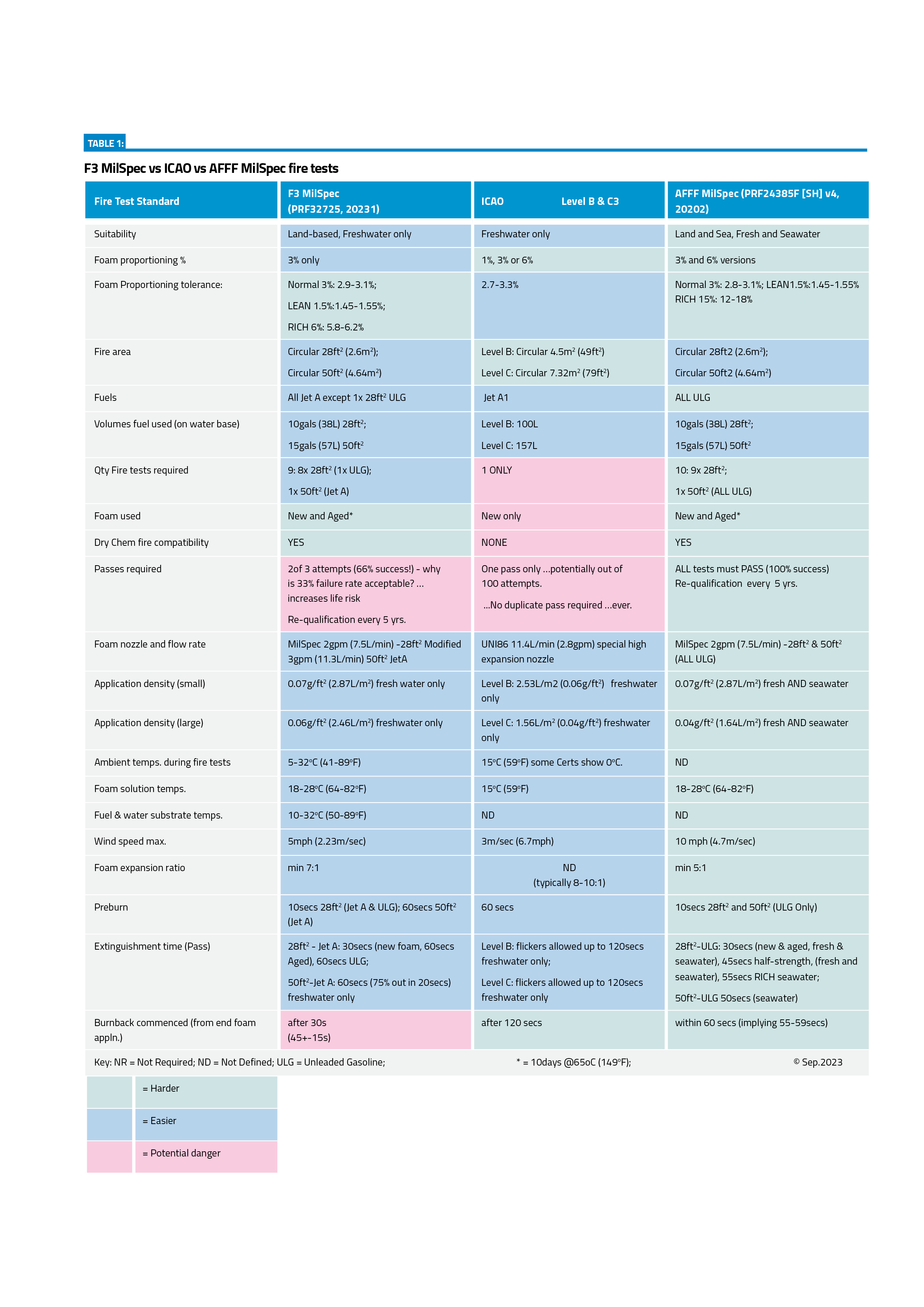

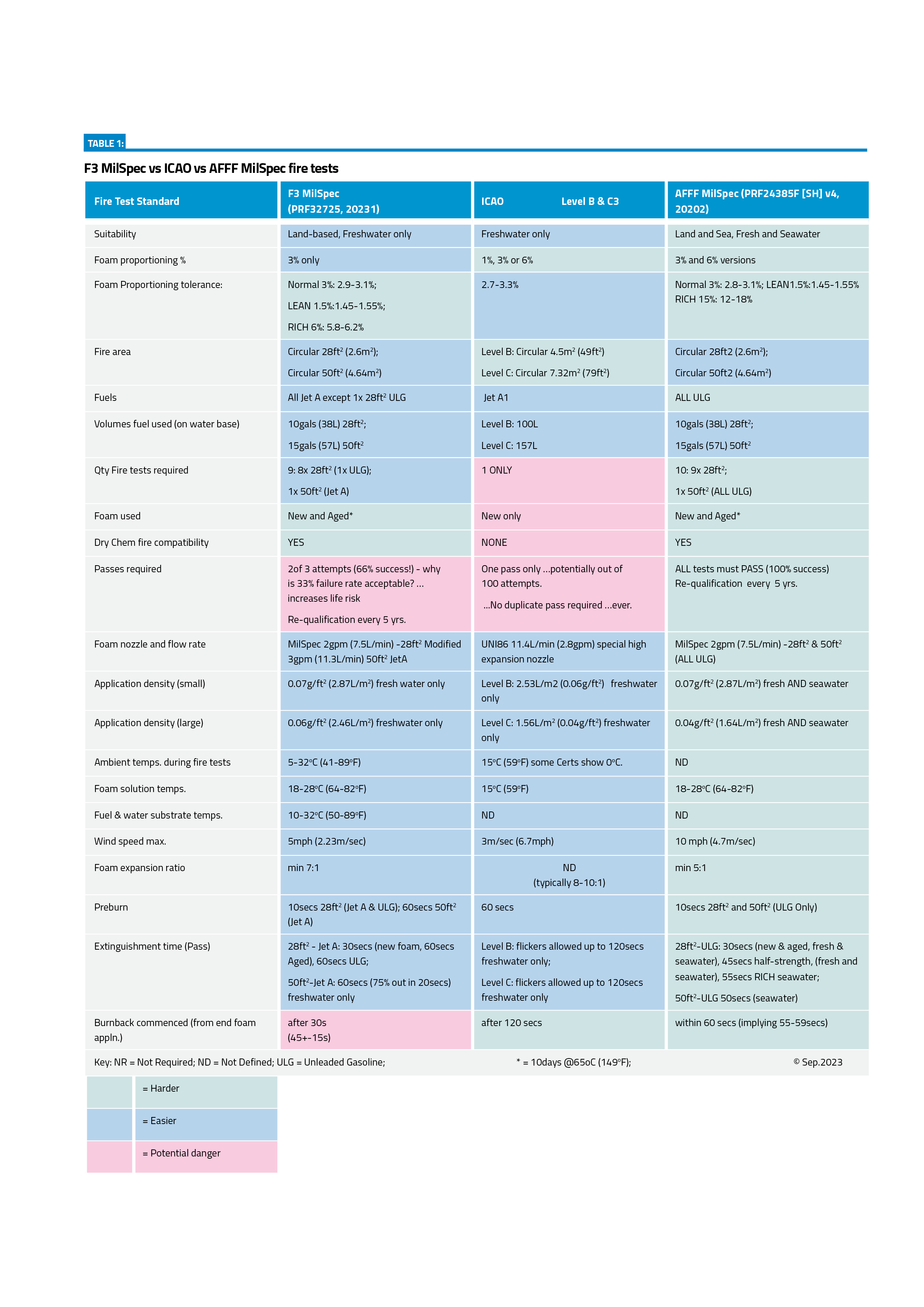

Comparison F3 MilSpec vs ICAO vs AFFF MilSpec fire tests

This comparison table highlights significant differences between new F31, existing MilSpec2 and ICAO3, including fire testing mostly on easier Jet A fuel, not gasoline. The new F3 MilSpec1 is more equivalent to ICAO level B not C, but with important extra testing beyond ICAO requirements3. With slower extinguishments and longer 50ft2 pre-burn, should fuel volumes be higher for F3 MilSpec? ICAO uses a special nozzle delivering generally higher foam expansion3 than proprietary nozzles widely used by ARFF Services (typically closer to 5:1 expansion1,2) tougher to pass than ICAO’s test nozzle nearer 10:1 expansion. 2020 NFPA Research Foundation testing17 confirmed F3s may require 25-50% higher application using 3-4:1 expansion than 7-8:1 expansion on volatile fuel fires like gasoline (relevant for on-airport car parks, including multi-storey often adjacent to terminal buildings). F3 MilSpec benefits from reduced wind speed and short delay before burn back testing, which does not represent realistic firefighting conditions.

Let’s not be fooled by a wide ambient temperature testing range either, as fire testing is always conducted under the minimum required temperature conditions1,3 to attain the best results for qualification. Another strong reason for verification testing requirements under hot summer conditions of 40oC or above, particularly when prevailing temperatures exceed the 38oC flashpoint of Jet A/A118 increasing vaporisation and volatility, so it behaves more like gasoline and is harder to extinguish.

ICAO objectives underline safety, but fall short on delivery

ICAO’s latest Global Aviation Safety Plan (GASP) 2023-2519 confirms “Values: GASP strives to enhance global civil aviation safety by:

- a) promoting a positive safety culture.

- b) recognizing and promoting the aviation sector’s responsibility for the safety of the public.

- c) encouraging collaboration, teamwork and shared learning in the management of safety.

- d) protecting safety data and safety information.

- e) promoting the sharing and exchange of safety information.

- f) taking data-driven decisions.

- g) prioritizing actions to address operational safety risks and organizational challenges through a risk-based approach.

- h) allocating resources to identify and analyse hazards, and address their consequences or outcomes through a risk-based approach; and

- i) proactively managing emerging issues.”

ICAO’s principal ARFF Services objective states: “To save lives in the event of an aircraft accident or incident. For this reason, the provision of means of dealing with an aircraft accident or incident occurring at, or in the vicinity of, an aerodrome assumes primary importance” (Chapter 10.5.7.1 of 2015 Airport Services Manual3). Providing such means – i.e. verifying firefighting foams will work effectively – should be of primary importance. Duty of care requires more thorough testing, including beyond the minimum 15oC ICAO3 requirement to verify year-round functionality.

Mandatory high temperature fire test requirements under MilSpec1,2 and ICAO3 should be an essential urgent inclusion to current regulations. This would ensure lives of passengers, flight crews and firefighters are not placed under unnecessarily increased danger, when operating under prevailing hot summer conditions. We should be avoiding risks of complacency potentially resulting from such a safe industry, few major fires and rigorous existing MilSpec fire testing, which has delivered a long history of keeping lives as safe as practically possible. Maintaining high safety levels without unintentional erosion or compromise, is critical to saving lives as aircraft fire conditions become more challenging.

About the author

Mike Willson is a firefighting foam and foam systems specialist with over 35 years’ experience of developing, testing, comparing and reviewing fire performance and environmental impacts of both fluorinated and fluorine free foams, their delivery devices and integrated fixed systems performances. He was instrumental in developing improved tank fire, bund protection and LNG recommendations in the EN13565-2: 2009 Foam Systems Standard. He also co-ordinated several emergency foam responses to major fire incidents worldwide.

An active member of Fire Protection Association Australia’s Special Hazards Technical Advisory Committee, he provides technical advice to a diverse range of stakeholders to better protect Class B flammable liquids with potentially suitable C6 and PFAS-free (F3) alternatives. He also keeps abreast of PFAS impacted site remediation, health impacts and PFAS removal and destruction technologies. Mike is a UL162 Task Group member reviewing inclusion of F3s into this important fire test approval standard, while also invited as a Technical Working Group member by Australia’s Civil Aviation Safety Authority (CASA) reviewing Aircraft Rescue and Firefighting Service (ARFFS) regulations.

His goal is ensuring life safety and fire protection capabilities are not unintentionally compromised, while achieving more holistic, effective and practical outcomes to adequately control major credible event fires, to benefit our environment, regulators and foam users.

References

- US Military Specification MIL-PRF-32725, 2023 – Performance Specification, Fire Extinguishing Agent – Fluorine Free Foam (F3) Liquid Concentrate for Land-Based, Freshwater applications, 6Jan.2023 https://media.defense.gov/2023/Jan/12/2003144157/-1/-1/1/MILITARY-SPECIFICATION-FOR-FIRE-EXTINGUISHING-AGENT-FLUORINE-FREE-FOAM-F3-LIQUID-CONCENTRATE-FOR-LAND-BASED-FRESH-WATER-APPLICATIONS.PDF

- US Military Specification MiL-PRF-24385F(SH) Amendment 4, 2020 – Fire Extinguishing Agent, Aqueous Film Forming Foam (AFFF) Liquid Concentrate, for fresh and Seawater, 7April 2020 https://quicksearch.dla.mil/Transient/D1698E19636543EABB1FB936AB3D69FB.pdf

- ICAO (international Civil Aviation Organization), 2015 – Airport Service Manual Doc 9137- AN/898 Part 1, Rescue and Fire Fighting 4th Edition , relevant Chapters 8 , 10,12, https://ufuav.asn.au/wp/wp-content/uploads/2016/11/operations-manual.pdf

- European Commission (EC) Cordis Sep.2014 – Fire risks assessment and increase of passenger survivability AIRCRAFTFIRE Report ID:265612 https://cordis.europa.eu/project/id/265612/reporting

- The Guardian, 19Jul.2022 – UK reaches hottest ever temperature as 40.2oC recorded at Heathrow [London airport] https://www.theguardian.com/uk-news/2022/jul/19/uk-weather-record-hottest-day-ever-heatwave

- New York Times, 10Jan.2023 – The last 8 years were the hottest on record https://www.nytimes.com/interractive/2023/climate/earth-hottest-years.html

- Wang K, Peng X, et al, Jan.2023 – Decreased Aircraft Take-off Performance Under Global Warming https://www.researchgate.net/publication/366853675_Decreased_Aircraft_Takeoff_Performance_under_Global_Warming

- US Naval Research Laboratory (Conroy & Anath), 2015 – Fuel surface cooling by Aqueous Foam: A Pool Fire Suppression Mechanism https://www.researchgate.net/publication/274737638_Fuel_Surface_Cooling_by_Aqueous_Foam_A_Pool_Fire_Suppression_Mechanism

- US Naval Research Laboratory (Conroy, Fleming & Anath), 2017 – Surface Cooling of a Pool Fire by Aqueous Foams https://www.researchgate.net/publication/311732795_Surface_Cooling_of_a_Pool_Fire_by_Aqueous_Foams

- FAA (Scheffey,Darwin and Hunt), 2012 – Methodologies for Calculating Firefighting Agent Quantities Needed to Combat Aircraft Crash Fires Report DOT/FAA/A11/29 http://www.tc.faa.gov/its/worldpac/techrpt/ar11-29.pdf

- US Naval Research Laboratory (Hinnant et al) 2017 – Influence of fuel on foam degradation for fluorinated and fluorine-free foams https://www.researchgate.net/publication/314107949_Influence_of_fuel_on_foam_degradation_for_fluorinated_and_fluorine-free_foams

- US Naval Research Laboratory (NRL-Snow, Hinnant et al), 2019 – Fuel for Firefighting Foam Evaluations: Gasoline v Heptane, NRL/MR/6123—19-9895 https://apps.dtic.mil/dtic/tr/fulltext/u2/1076690.pdf

- US Naval Research Laboratory (NRL – Hinnant, Snow, Ananth et al), Nov. 2019 – “Characterising role of Fluorocarbon and Hydrocarbon Surfactants in Firefighting Foams for Fire Suppression” https://link.springer.com/article/10.1007/s10694-019-00932-7

- US Naval Research Laboratory (NRL – Hinnant, Ananth, Farley, Snow et al) – May 2020 – Extinction Performance Summary of Commercial Fluorine Free Firefighting Foams over a 28ft2 Pool Fire Detailed by MIL-PRF-24385, Report NRL/MR/6185-20-10, 031 https://apps.dtic.mil/sti/pdfs/AD1100426.pdf

- US Naval Research Laboratory (NRL – Hinnant, Ananth, Farley, Snow et al) – May 2020 – Extinction Performance Summary of Commercial Fluorine Free Firefighting Foams over a 28ft2 Pool Fire Detailed by MIL-PRF-24385, Report NRL/MR/6185-20-10, 031 https://apps.dtic.mil/sti/pdfs/AD1100426.pdf

- NFPA 403:2018 Standard for Aircraft Rescue and Firefighting Services at Airports https://www.nfpa.org/codes-and-standards/all-codes-and-standards/list-of-codes-and-standards/detail?code=403

- National Fire Protection Association (NFPA) of America, Research Foundation, 2020 – “Evaluation of the fire protection effectiveness of fluorine free firefighting foams”, https://www.iafc.org/docs/default-source/1safehealthshs/effectivenessofflourinefreefoam.pdf

- Air BP, Mar.2021 – Jet A1 Safety Data Sheet skyfuel.com.au/wp-content/uploads/2021/02/Jet-A-1-Australia-SDS.pdf

- ICAO, 2022 – Global Aviation Safety Plan (GASP), Doc. 10004, 2023-2025 https://www.icao.int/safety/GASP/Pages/Home.aspx