Ensuring a safer future for the aviation industry

- Like

- Digg

- Del

- Tumblr

- VKontakte

- Buffer

- Love This

- Odnoklassniki

- Meneame

- Blogger

- Amazon

- Yahoo Mail

- Gmail

- AOL

- Newsvine

- HackerNews

- Evernote

- MySpace

- Mail.ru

- Viadeo

- Line

- Comments

- Yummly

- SMS

- Viber

- Telegram

- Subscribe

- Skype

- Facebook Messenger

- Kakao

- LiveJournal

- Yammer

- Edgar

- Fintel

- Mix

- Instapaper

- Copy Link

Posted: 18 February 2013 | Kim Thorbjørn Olsen Assistant Fire Chief, Copenhagen Airport | No comments yet

In May 2012, the UK Civil Aviation Authority (CAA) and other specialists from different parts of the aviation industry set up large scale fire tests to compare compressed air foam systems (CAFS) with normal aspirated foam, using different foam products for Aviation Rescue and Fire Fighting (ARFF) use to International Civil Aviation Organization (ICAO) Level B and Level C, including a comparison of fluorine-free foam with AFFF. These tests took place at the Centre National de Prévention et de Protection (CNPP) research facilities in Vernon, France, with the participation of UK CAA regulators, manufactures from the aviation and ARFF industries and airport fire fighters.

In May 2012, the UK Civil Aviation Authority (CAA) and other specialists from different parts of the aviation industry set up large scale fire tests to compare compressed air foam systems (CAFS) with normal aspirated foam, using different foam products for Aviation Rescue and Fire Fighting (ARFF) use to International Civil Aviation Organization (ICAO) Level B and Level C, including a comparison of fluorine-free foam with AFFF. These tests took place at the Centre National de Prévention et de Protection (CNPP) research facilities in Vernon, France, with the participation of UK CAA regulators, manufactures from the aviation and ARFF industries and airport fire fighters.

CAFS have been used to fight fires for many years. Traditionally CAFS have been used to fight Class A/structural fires and not Class B/fuel fires, except under research conditions. CAFS are simple systems in which high pressure air is injected into the water/foam solution before leaving the piping leading to the turret or hose line. Traditionally Airport Crash Tenders have operated using aspirating turrets and nozzles.

“This testing was an excellent example of the regulator, operators and manufacturers working together for the common aim of improving safety in aviation,” says Simon Webb, who is leading the project for the UK CAA. “The results of this research have delivered a key objective of the CAA Safety Plan to encourage the use of new technology in firefighting and will direct us on the way forward with the CAFS technology.”

The tests also found that the new generation fluorine-free firefighting foams, which do not contain fluorinated products associated with the problem of environmental persistence, per – formed just as well as the currently used aqueous film-forming foams (AFFF). Thus the results identify those products and systems which are capable of satisfying both fire-fighting and environmental objectives.

Industry partners in the tests included the UK Airport Operators Association, Copenhagen Airport and the Singapore-based Changi Airport Group.

Environmental issues with fluorine and the organohalogens (fluorosurfactants) in AFFFs have resulted in a process of these foams being replaced by new fluorine-free foams. These fluorine-free foams are also fully ICAO level B approved and it was with great interest to see how these performed on large scale fires.

Results from these tests clearly show that CAFS has a tremendous capability for knocking down the fire when compared to foam produced with a normal aspirated nozzle. The CNPP results showed that CAFS is actually 40 per cent more efficient. Moreover, test results showed that the new fluorine-free foam was just as effective and efficient as AFFF.

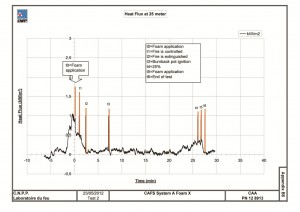

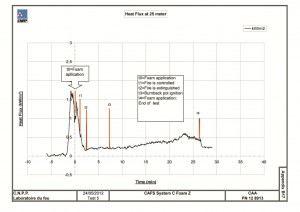

Typical results for these CAFS fire tests are shown in Figure 1 and Figure 2, in which results are compared for an ICAO level B compliant AFFF (Foam X) and an ICAO Level B compliant fluorine-free foam (Foam Z). Clearly there are no significant differ – ences in performance.

Testing at CNPP and results

On the first day of the testing period, participants decided how the test procedure should best be organised in order to achieve good objective results. The plan finally chosen was to combine CAF systems with different foam agents which had not been used in combination together in the past. Before starting with the large-scale fire tests, the systems were optimised. CNPP staff measured the water flow rate, expansion ratio, as well as the 25 and 50 per cent drainage times.

In order to calculate the water flow rate, a 1000-litre IBC container was filled for 20 seconds and then weighed. The determination of the quantity of foam used was done by weighing the difference between the filled and empty IBC container. This was done for every test.

Measurement of the foam quality was generally done according to NFPA requirements, except the foam shield was placed at the end of the throw range and not at 2/3 of the throw range, as per usual. All measurements were done by CNPP staff.

Test procedure and tactic

At the beginning of the tests, the pool was filled with water, to at least a depth of 10cm. Afterwards 1,500 litres of kerosene was poured into the pool and set on fire. After the whole pool was alight, the kerosene was left to burn for another 60 seconds before extinguish – ment began.

The tactics to be used were discussed by the group of all participants and were defined as:

● The fire should be fought in a static way from a fixed position for two minutes

● If the fire could not be extinguished then the fire fighters should wait for 30 seconds and start extinguishing again in a dynamic way until the fire was totally extinguished

● After extinguishment a burn-back test had to be done after waiting five minutes (for this, a burn-back pot (sleeve) was put into the pool, the foam in the pot was cleared away and 20 litres of heptane was poured into the pot and lit).

Working with new technology at Copenhagen Airport

Copenhagen Airport’s Fire Service mission statement and vision strategy is to: ‘Always keep a high level of professionalism, resource fulness and ability to implement new technologies replacing old ones. To ensure an efficient operation within CPH. And to ensure a high level of satisfaction from the airlines and their passengers.’

Copenhagen Airport strives to be the best run airport in the world. In order to maintain a leading international position, it is constantly developing – by experimenting and questioning routines and procedures, staff are able to develop their skills and enhance the procedures. The Airport’s goal is to seek change, not for change’s sake, but to create something better.

Copenhagen Airport’s Fire Service has always had to deal with the challenge of low staffing levels. New techniques have always been adapted for use by the service and experimenta – tion has always been allowed – as long as all the demands imposed by regulators and regulations are also met. Examples of this approach include fighting interior aircraft fires with high pressure nozzles and one-man Crash Tenders.

Over the last five to six years Copenhagen Airport Fire Service has worked on operational and tactical improvements. The whole fleet of crash tenders has been upgraded with Rosenbauer CA-5 Panthers. One Panther is provided with FLASH™ CAFS (air bottles instead of a compressor – this works extremely well with large flow rates) on the main turret; two of the other Crash Tenders are fitted with high reach extended turrets (HRET) and the Hydro-Chem dual system.

For environmental reasons, AFFF was replaced with fluorine-free ICAO level B foam – Solberg 3X6 RF re-healing ATC foam. The Copenhagen Airport Environment Department has, for many years, had environmental concerns, especially about the fluorochemicals that are in the AFFF in use at the airport. This meant that there were restrictions introduced on using this foam for testing and training. Copenhagen Airport was the first international airport to have implemented fluorine-free foam into the Fire Service for operational use as early as 2009. NFPA 403 testing of all foam outlets and foam proportioning systems on all vehicles was done in conjunction with the foam manu – facturer Solberg foam and the vehicle manufacturer Rosenbauer with all vehicles and foam systems being thoroughly performance tested before this new type of foam was put into service.

Environmental problems with AFFF foams

In 2008-2009 a series of articles appeared in the Industrial Fire Journal and Fire & Rescue magazine, which started to focus on the prob – lems and concerns with environmental problems associated with AFFFs.

These articles have had a tremendous effect on a lot of European airports’ awareness of the problem. One article in particular, written by Dr Roger Klein, one of the world’s leading experts on firefighting foams, with a background as a physical chemist, medic and long-term adviser to the national Fire Service, entitled ‘Contaminated Firewater – Protecting the Environment’1, under – lined the serious concerns and findings from a study that took place in Norway.

Following increased awareness, all major Scandinavian airports and firefighting training grounds now attract attention from national environmental regulators. The European Union Commission for Environment has also become aware of the problem, resulting in a ban on the use of all fluorine-containing foams based on PFOS fluorosurfactants for firefighting within Member States from 27 June 2011.

Airport Fire Services

ARFF is a highly specialised component of the fire services. An aircraft accident presents different hazards, which threaten aircraft occupants, the community, the environment and emergency responders. ARFF crews must therefore respond quickly and with precision to minimise the loss of life, injuries and other potential dangers. Fortunately, serious accidents are fairly rare, but that benefit means that experience can only be built up through training and learning from others, as incident experience is, thankfully, not common.

Within Aviation Fire Services, regulation and legislation are rooted in the ICAO’s recommenda – tions, which are often incorporated into a country’s national legal framework, although some countries take these recommendations further than others. Most airlines require ICAO recommendations to be met as a minimum airport standard. But Fire Service traditions are increasingly interfering with progress – just because it’s always been done a certain way, does mean it’s the best way. Keeping up with traditional and regulations is not always enough. The key is to be prepared.

Crisis management and preparation will always be an ongoing process. The best possible way to manage a crisis is using the resources of a Fire Service. Thinking ‘outside the box’ is important for progress, improvements and efficiency, and being prepared is crucial to ensure safety now and in the future.

A safer future for the aviation industry

The tests at CNPP have shown that CAFS has advantages in extinguishing fires compared to aspirated foam, although by how much is not clear (very approximately 40 per cent more effective). These tests also pointed out other very important factors like environmental influences and tactics, which have a significant impact on the extinguishment time and therefore also on the quantity of extinguishing agent used. These factors have a tremendous effect on the success of extinguishing a fire. The tests also showed that ICAO Level C is characterised by almost the same extinguishment time and requires a similar quantity of extinguishing agent as ICAO Level B but Class C foams contain much more fluorine which in turn has a negative impact on the environment.

I have no doubt at all that CAFS and fluorinefree foam will improve both aviation safety and the environment impact of fire service operations at airports. Just as important is the safety of the firefighters whom we send straight into the danger zone in a worst case scenario. Greater efficiency and faster control of the situation will certainly also give firefighters more confidence in coping with the situation. A new Rosenbauer Panther with CAFS on all low pressure outlets is well on its way and expected to be put into service at CPH in November 2012.

The CAA put forward a proposal to the ICAO Rescue and Fire Fighting Working Group at their last meeting in Montreal, Canada, for the use of CAFS on airport fire vehicles. It was accepted. If things go as planned, a new ICAO standard and procedure based on this CAFS recommendation will be implemented in the ICAO Airport Service Manual in November 2013. Great news for the future of aviation safety!

This article first appeared in the Singapore Aviation Management Journal 2012.

Reference

‘Contaminated Firewater – Protecting the Environment’, Fire & Rescue, March 2009 (vol. 73, pp. 26-29)

Biography

Kim Thorbjørn Olsen has worked within the aviation world for more than 35 years. Before taking a position as firefighter at Copenhagen Airports Airport, Kim served nine years in the Security/Airport Police. A promotion and a new job at Roskilde Airport meant getting involved with ARFF. After returning to the Copenhagen Airport’s Fire and Rescue Department in 1989, Kim worked his way through the ranks and is currently Copenhagen Airport’s Assistant Fire Chief and Chief Instructor at the Copenhagen Airport ARFF School. Kim is also an Instructor in ARFF on all Danish Incident Command courses at DEMA, the Danish Emergency Services College, and a member of both IAFPA and the ARFFWG, holding a position as a Manager for section 11 in the ARFFWG and functions as a Liaison Officer between the two organisations.