Airfield Lighting: The long-term performance of LEDs

- Like

- Digg

- Del

- Tumblr

- VKontakte

- Buffer

- Love This

- Odnoklassniki

- Meneame

- Blogger

- Amazon

- Yahoo Mail

- Gmail

- AOL

- Newsvine

- HackerNews

- Evernote

- MySpace

- Mail.ru

- Viadeo

- Line

- Comments

- Yummly

- SMS

- Viber

- Telegram

- Subscribe

- Skype

- Facebook Messenger

- Kakao

- LiveJournal

- Yammer

- Edgar

- Fintel

- Mix

- Instapaper

- Copy Link

Posted: 16 April 2014 | Jean Paul Freyssinier, Senior Research Scientist & Adjunct Assistant Professor, Lighting Research Center, Renesselaer Polytechnic Institute | No comments yet

Jean Paul Freyssinier provides a detailed summary of the Lighting Research Center – Rensselaer Polytechnic Institute’s work on understanding the useful life of airfield LED luminaires…

In just the past few years we have seen light-emitting diodes (LEDs) make impressive progress in terms of light output, colour properties, efficacy (measured in units of light (lumens, lm) per electric watt, or lm/W), and potential for long life. These improvements, paired with significant reductions in costs, have resulted in many more applications using LEDs, from consumer electronics to cars to general illumination indoors and out.

For aviation lighting, the use of LEDs has always been a sensible option because LEDs are particularly suited for applications in need of coloured light and because signals and other visual aids in airports do not require much light output necessarily, so even early generation LEDs were able to provide suitable solutions compared to traditional incandescent sources. Thus, with the potential to improve visibility to pilots, energy savings, and long life, airports throughout the world are transitioning to LED-based solutions at an increasing rate.

Now that the light output and efficacy of LEDs has met or surpassed those from other light sources, the focus in most applications, including aviation lighting, has shifted to other important issues, such as long-term performance, system reliability, and initial cost. The potential for long life is particularly relevant to airport administrators and decision-makers because it can translate into more reliable operations and reduced maintenance costs, especially considering the demanding conditions found in airports. However, LED luminaires (fixtures), and in particular airfield luminaires, are relatively new to the market and no sufficient long-term performance test results are currently available2. Notably, at this time there is no definition of ‘useful life’ specific to aviation lighting products.

Why do we need a definition of useful life?

While LEDs could last for many thousands of hours under certain conditions, the life of the LED itself, and more importantly, that of the complete luminaire, still depends on the system integration and the actual conditions in which the luminaire is used. Application conditions that could have an impact on the expected life of the luminaire include, primarily, the temperature of operation, on-off cycling patterns, and humidity. Because LEDs do not have filaments that break or wear off, when operated under nominal conditions they tend to last for a long time. However, their light output decreases and the colour of their light shifts over time, with the rate of depreciation increasing at higher operating temperatures. The implication for practice is that at some point in time the loss of light output or the colour shift may render the LED source outside the specifications for a given application or purpose; while the LEDs may technically still be operating, they would no longer be considered useful.

For this reason, the lighting industry adopted a definition of useful lifetime as a function of LED light output (or lumen) maintenance and colour shift (ASSIST 2005). For general illumination, a lumen maintenance value of 70 per cent (typically denoted at L70) is a reasonable expectation for most applications where light levels are not critical to the tasks at hand. Consequently, manufacturers rate the useful life of their products as the time (in hours) until the light output has decreased by 30 per cent for a given temperature of operation. In North America, the Illuminating Engineering Society (IES) formalised the test procedures to measure LED lumen maintenance in publication IES-LM-80-08 (IESNA 2008). This test is conducted at three LED board temperatures to capture LED performance over a range of conditions that would be somewhat representative of realistic applications. By using mathematical models, estimates of lumen maintenance can be made for other temperatures within the test range.

It is worth emphasising that LEDs are only one part of a system that usually includes other components such as secondary optics, mechanical and thermal management parts, and electrical gear. In the end, the useful life of the luminaire will be determined by the reliability of all parts combined. Since any of the parts could fail before the lumen maintenance of the LEDs has reached a given criterion, lumen maintenance cannot and should not be used to estimate the useful life of a luminaire as a whole. To complicate the situation further, different luminaires using the same LED package can differ in performance and reliability depending on how the system was designed and integrated. Similarly, a given luminaire will perform differently depending on the actual conditions of operation. Although work is in progress, there is still no standardised testing methodology to measure or predict the reliability of luminaires. In the meantime, a functional definition of useful life for LED-based airfield luminaires is needed. Unlike many general illumination applications where a 30 per cent drop in light output may be inconsequential to many end users, airfield luminaires are meant to provide meaningful visual guidance to pilots under different conditions, but particularly in low visibility. Thus, airfield luminaires can only be considered useful if they meet all their photometric requirements at all times. These requirements include not only how much light is produced but also its spatial distribution and its colour. In combination, these criteria could be used as the basis for a functional definition of airfield luminaire life.

How can we move toward a definition of useful life?

Understanding the long-term performance of LED-based airfield luminaires under realistic conditions is the first step to establishing a functional definition of useful life. With this objective in mind, the Lighting Research Center began a long-term study in the autumn of 2011 with funding from the Federal Aviation Administration (FAA) Visual Guidance Program to gather initial data on light output depreciation, colour shift, and intensity distribution changes from a limited number of in-ground luminaires as a function of temperature of operation. The samples tested included three red/white directional runway centerline luminaires (type L-850A) and three white touchdown zone luminaires (type L-850B). In total, the luminaires were tested for more than 10,000 hours between October 2011 and January 2013.

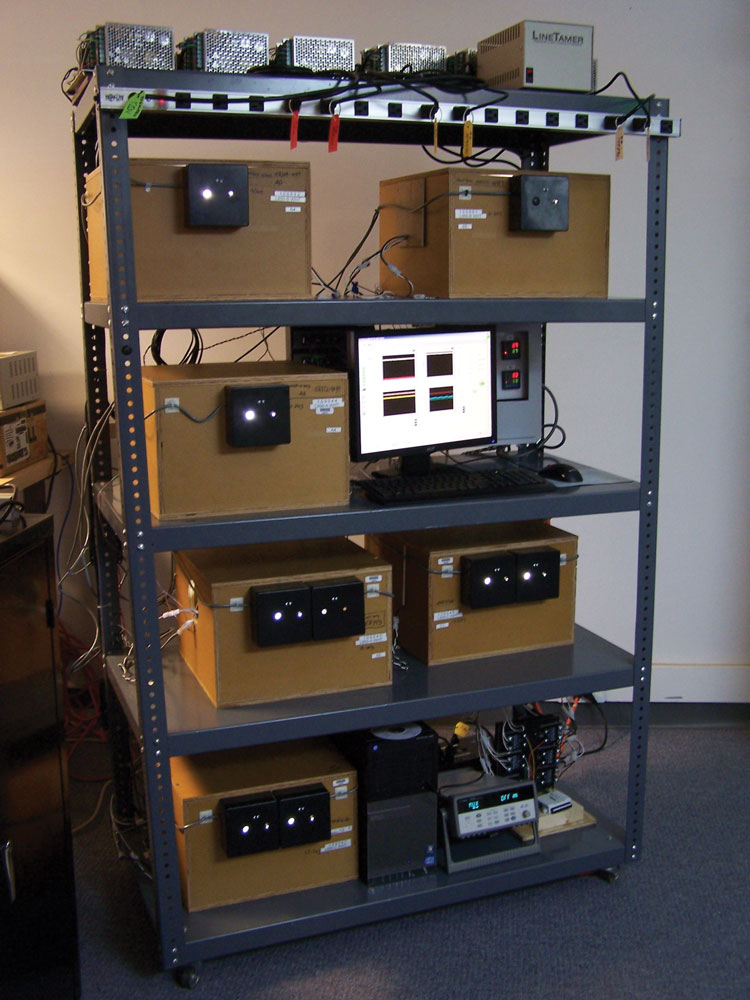

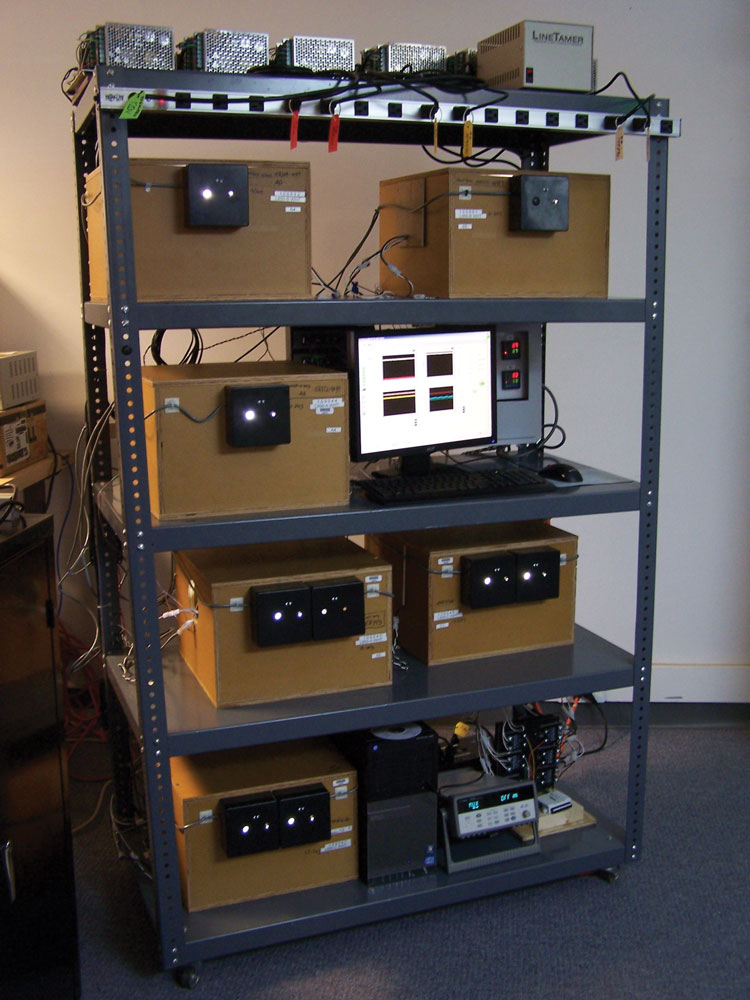

The study was designed to observe the relative change in photometric characteristics as a function of LED operating temperature. During the test, each luminaire was installed in a customised test chamber designed to operate the luminaire continuously with a nominal 6.6A current and at a predetermined temperature. The selected test LED board temperatures were nominally 55°C, 80°C, and 100°C and were kept constant for the duration of the test. Each chamber included the required heating elements, controls, and sensing probes to monitor the performance of the luminaire. Before the beginning of the test, the intensity distribution of each luminaire was captured using a bar goniophotometer and kept as a reference to check against at the end of the study. The relative light output of each luminaire was monitored every four hours using a photometrically calibrated photosensor. To monitor the changes in the colour of the light, the spectral power distribution was measured at least once every 1,000 hours. Figure 1 shows a picture of the overall set-up including the six testing chambers and the data logging equipment.

Test rack with the six LED luminaire samples under long-term life test. Each luminaire sample was housed in a wooden test chamber along with the required heating elements, controls, and sensing probes to monitor the performance of the luminaire. A computer program logged the relative light output and electrical input current to each luminaire

What were the results of the long-term test?

Of the six samples under test, three ceased to operate as a consequence of failures in the LED driving circuit. These failures happened at 560 hours of operation (100°C condition) and at 3,360 hours of operation (80°C condition) for two of the L-850B samples, and at 7,630 hours of operation (100°C condition) for one L-850A sample. These results help make the point that luminaire reliability involves much more than just LED light output depreciation.

All white-light samples exhibited some degree of colour shift over the test period and all of them in the ‘yellow’ direction, which is an indication of LED lens or encapsulant degradation due to temperature. By all measures, the colour shift in all cases would have been noticeable to the eye, but more importantly, the end result was outside the white colour boundary specified by FAA.

The final test was a measurement of the intensity distribution to determine if heat had influenced in any way the optics of the samples. For this test, the three samples that operated the longest amount of time at the highest available temperatures were measured in the bar goniophotometer in a similar way as before the long-term test started. For the samples tested, the changes in beam distribution were very small, generally of less than one degree, which wouldn’t present a problem under application conditions.

Conclusion and future steps

Undoubtedly, LEDs offer many potential benefits to aviation lighting, including better conspicuity to pilots, energy savings, and lower maintenance costs through a long life. However, reasonable estimates of such benefits depend on knowing the useful lifetime of the luminaire in a given application. Unfortunately, long-term performance of LED airfield luminaires has not been systematically documented. The recent work described in this article is a starting point to inform a future proposed definition of useful life, which should be based on the ability of a luminaire to meet target photometric requirements at all times. As expected, the results from this test showed that LED products can perform very differently depending on how the system was designed and the actual conditions of operation. The results also help make the point that a definition of useful life needs to incorporate more criteria than just the light output depreciation of the LEDs. Although in principle a definition of useful life based on meeting photometric requirements is sensible, there is one question still open, which is how can the aviation industry monitor each luminaire to ensure all of them meet those photometric requirements?

This last point is of no small significance. Visual inspection of lights in the field is still the primary means to determine if a light needs replacement or maintenance. With incandescent sources, the task was simpler because the light was either on or off. With LEDs, notwithstanding the early failures that would result in a luminaire being off, determining visually if a given luminaire has fallen out of light output or colour specifications is a more complicated task that may eventually require optical monitoring devices in each luminaire.

Acknowledgement

The research described in this article was conducted by the Lighting Research Center at Rensselaer Polytechnic Institute under FAA cooperative agreement 2010G013, with the guidance of Donald Gallagher, FAA Visual Guidance Program Manager, Airport Safety R&D. For more information about airfield lighting research, visit the Lighting Research Center’s Aviation Research page: www.lrc.rpi.edu/programs/solidstate/aviation.asp.

References

- Navigant Consulting, Inc. 2012. 2010 U.S. Lighting Market Characterization. Washington, DC: U.S. Department of Energy. Available online from http://apps1.eere.energy.gov/buildings/publications/pdfs/ssl/2010-lmc-final-jan-2012.pdf

- Bullough, J. D. 2012. Issues With Use of Airfield LED Light Fixtures, ACRP Synthesis 35. Washington, DC: Transportation Research Board, National Research Council, National Academies.

Further reading

- Alliance for Solid-State Illumination Systems and Technologies (ASSIST). 2005. ASSIST recommends: LED life for general lighting. Vol. 1 Iss. 1-7. Troy, NY: Lighting Research Center.

- Illuminating Engineering Society of North America (IESNA). 2008. IES-LM-80-08 Approved Method: Measuring Lumen Maintenance of LED Light Sources. New York, NY: IESNA.

Biography

Jean Paul Freyssinier is a Senior Research Scientist and Adjunct Assistant Professor at the Lighting Research Center, Rensselaer Polytechnic Institute. His research includes solid-state lighting and the spectral effects of lighting. He is the author of more than 35 technical articles, and co-author of two patents on remote phosphor technology.

LEDs and human factors

Dr John D. Bullough, Senior Scientist at the Lighting Research Centre, Rensselaer Polytechnic Institute

In addition to the durability, long operating life and energy efficiency of LEDs, they also have several human factors advantages, which the Lighting Research Centre has been investigating in cooperation with the FAA:

- Wide range of correlated colour temperature (CCT) for white light, and more saturated colour than incandescent signal lights

- Instantaneous rise and decay times.

With regard to the colour characteristics of LEDs, the ability to create white light with higher CCT results in more accurate identification of white signal lights. Incandescent signals, especially when dimmed to lower intensity steps, produce illumination that is regularly confused with yellow light. For coloured signal lights, LRC research has also shown that the saturation of LED colour is beneficial for correct identification, for both colour-normal and colour-deficient observers1.

For flashing signals like runway end identifier lights (REILs) and obstruction lights, the ability to switch LEDs on and off rapidly allows the use of multiple-pulse light flashes consisting of several short pulses often appearing as a single flash, similar to signals using xenon strobes. FAA specifies the performance of flashing lights in terms of ‘effective intensity’, defined as the intensity of a steady light with the same visibility as the flashing light. Effective intensity predicts the relative visibility of single-pulse flashing signals well2, but the FAA’s current definition of effective intensity for multiple-pulse flashes overestimates their effectiveness when the light pulses are longer than those produced by xenon strobes3. A definition used by ICAO better predicts the visibility of multiple-pulse flashes, placing LEDs and other sources on the same technology-neutral playing field.

The LRC’s research on aviation lighting and LEDs can be found online at: www.lrc.rpi.edu/programs/solidstate

References

- Bullough JD, Skinner NP, Bierman A, Milburn NJ, Taranta RT, Narendran N, Gallagher DW. 2012. Nonincandescent Source Aviation Signal Light Colors, DOT/FAA/TC-TN12/61. Washington: FAA.

- Bullough JD, Skinner NP. 2013. Conspicuity of flashes of light: Interactions between intensity and duration. Journal of Modern Optics 60: 1193-1199.

- Bullough JD, Skinner NP, Taranta RT. 2013. Characterising the effective intensity of multiple-pulse flashing signal lights. Lighting Research and Technology 45: 377-390.

Biography

John D. Bullough is a Senior Research Scientist and Adjunct Assistant Professor at the Lighting Research Center, Rensselaer Polytechnic Institute, where he coordinates the Center’s Transportation Lighting and Safety Program. He is a Fellow of the Illuminating Engineering Society and is the author of more than 300 publications on lighting and vision.